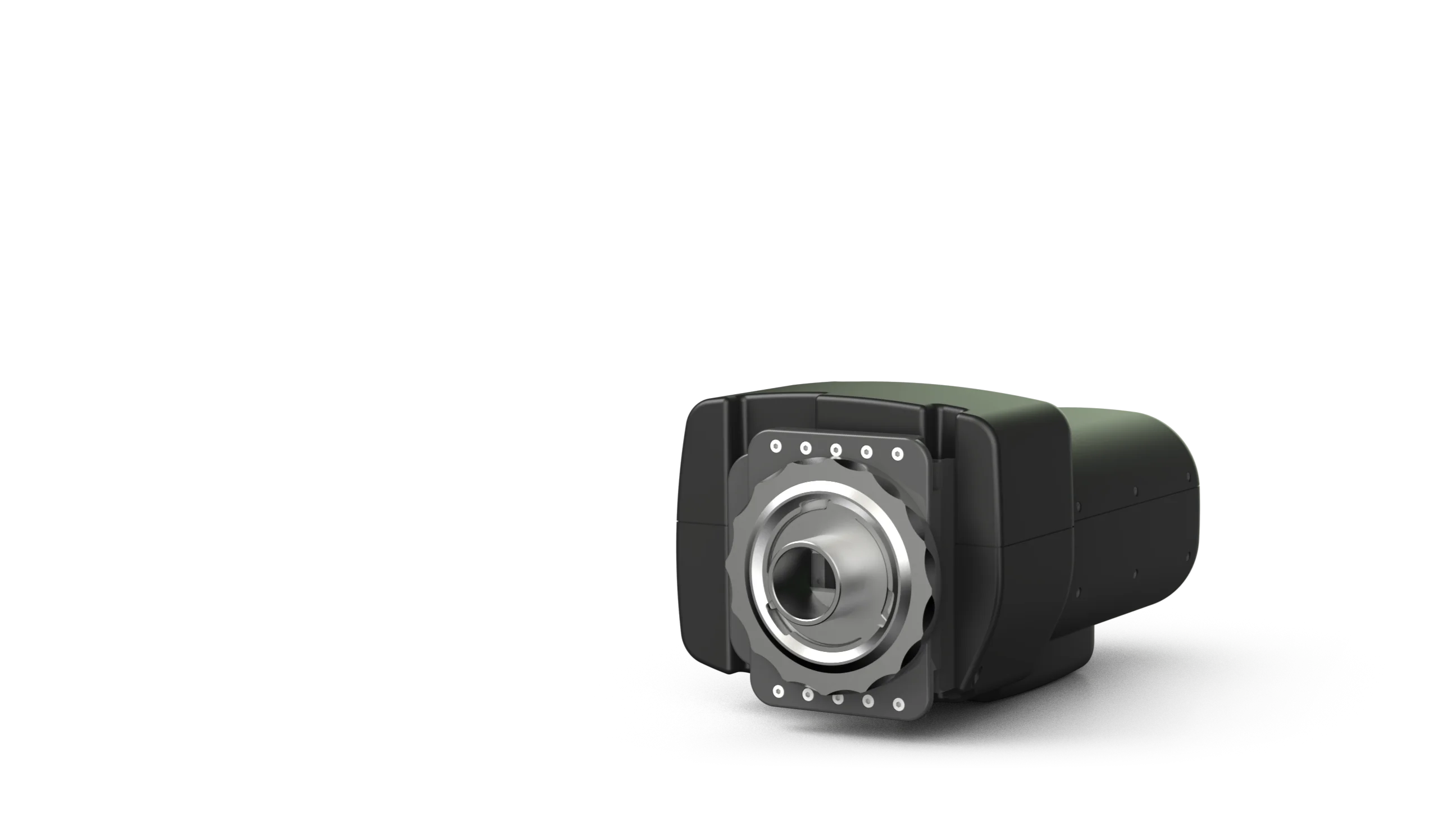

OCTOPUS 2 is a handheld robotic interferometer designed for maintenance inspection of multi-termini fiber optic connectors (MIL-DTL-38999 style and similar) installed inside an aircraft or marine vessel.

The OCTOPUS 2 uses a multi-axis motion system to scan the 3D surface and measure geometry parameters for each terminus of a fiber optic connector automatically.

Stationary connectors can now be inspected inside patch-panels, server boxes, and other optical-network units without being dismantled for inspection.

OCTOPUS 2

robotic interferometer for inspection of multi-termini fiber optic connectors.

Aerospace, marine and military vehicle field service.

On-site inspection in harsh environments like oil & gas, backbone telecom etc.

Compact handheld form factor

Inspect stationary optical connectors in areas or locations with limited space such as aircrafts, ships, different vehicle platforms, and others.

Dimensions (H × W × L): 90 × 118 × 184 mm (3.5 × 4.6 ×7.24 inches)

™ Software

™ Software

Start screen

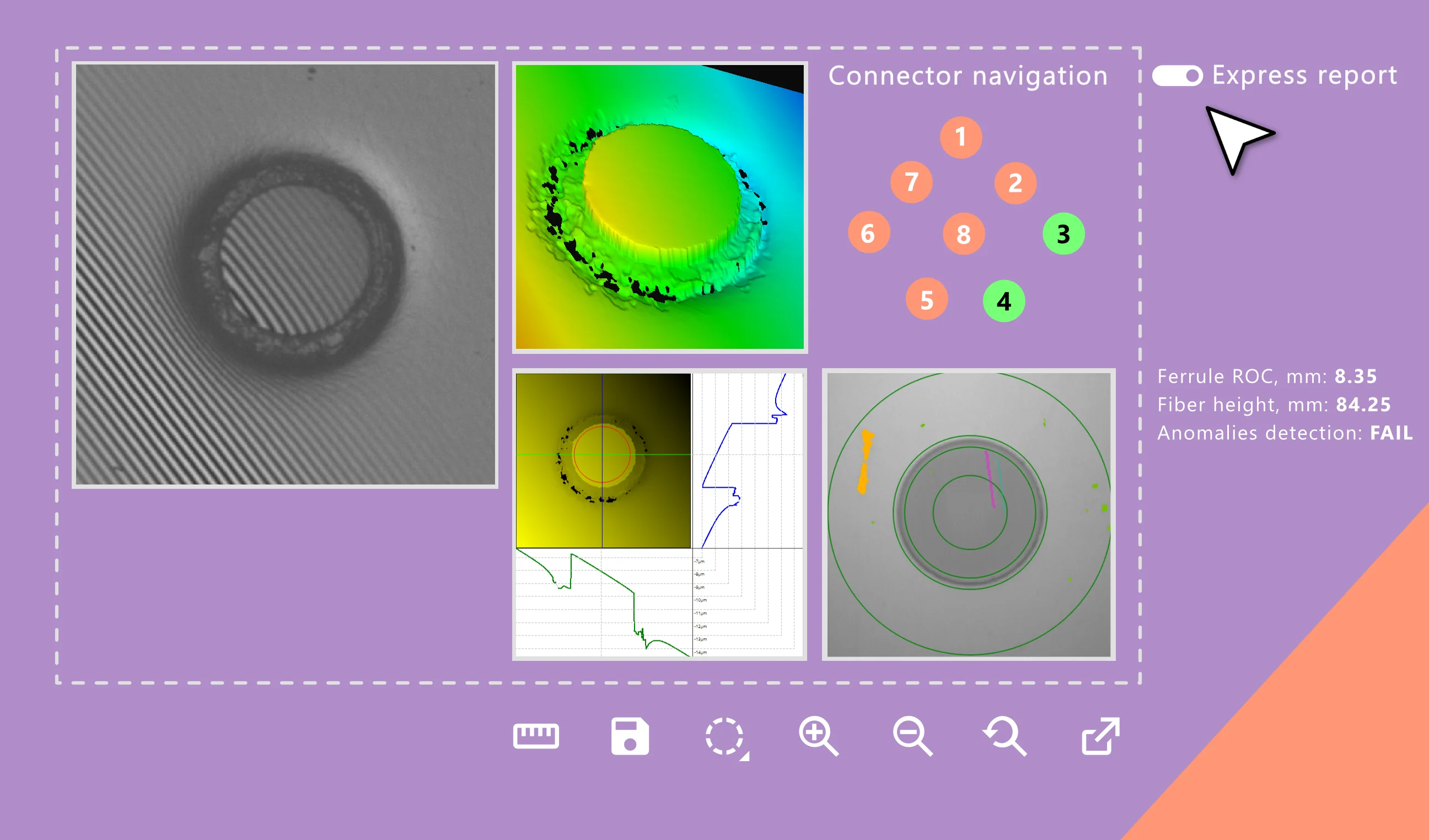

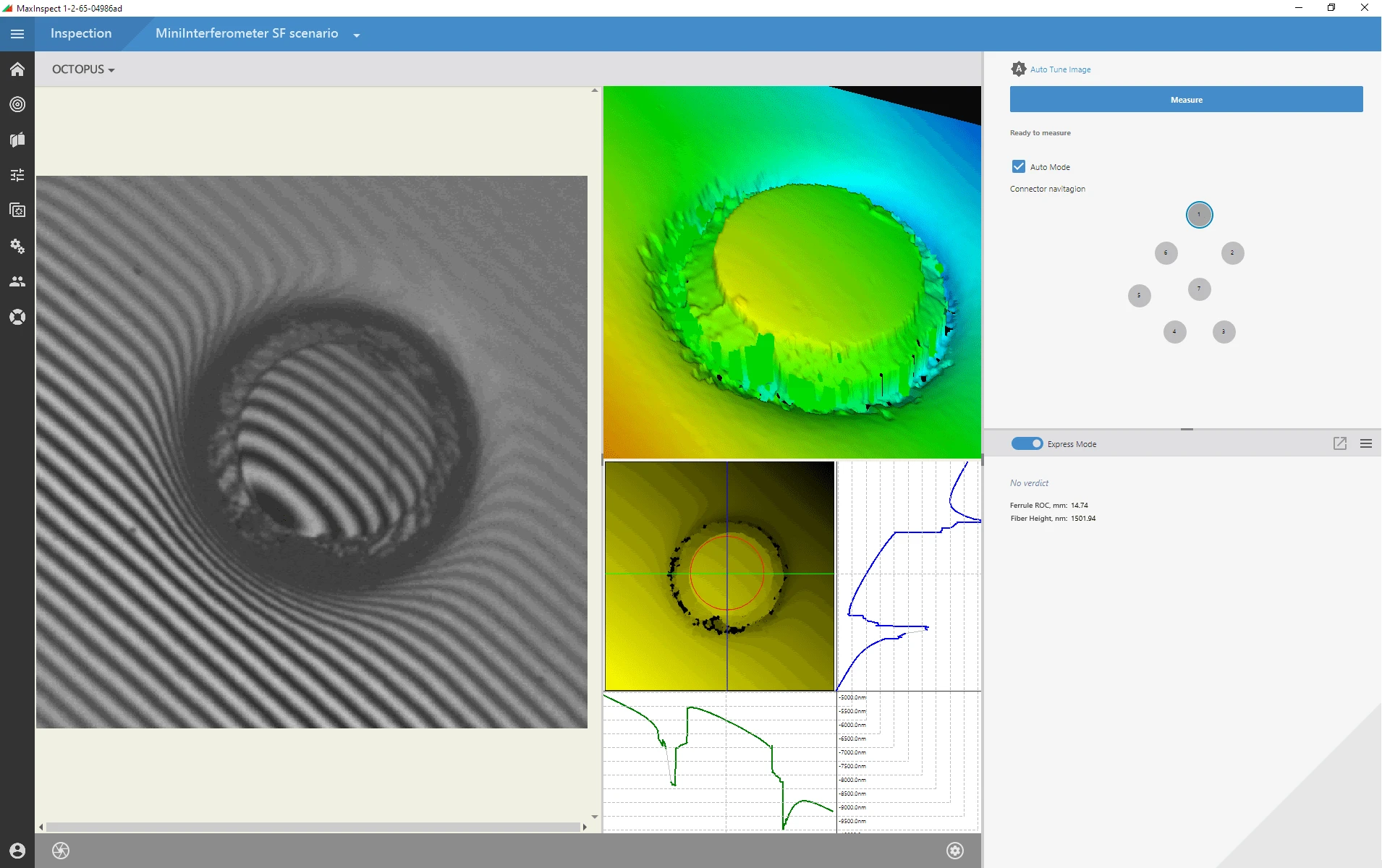

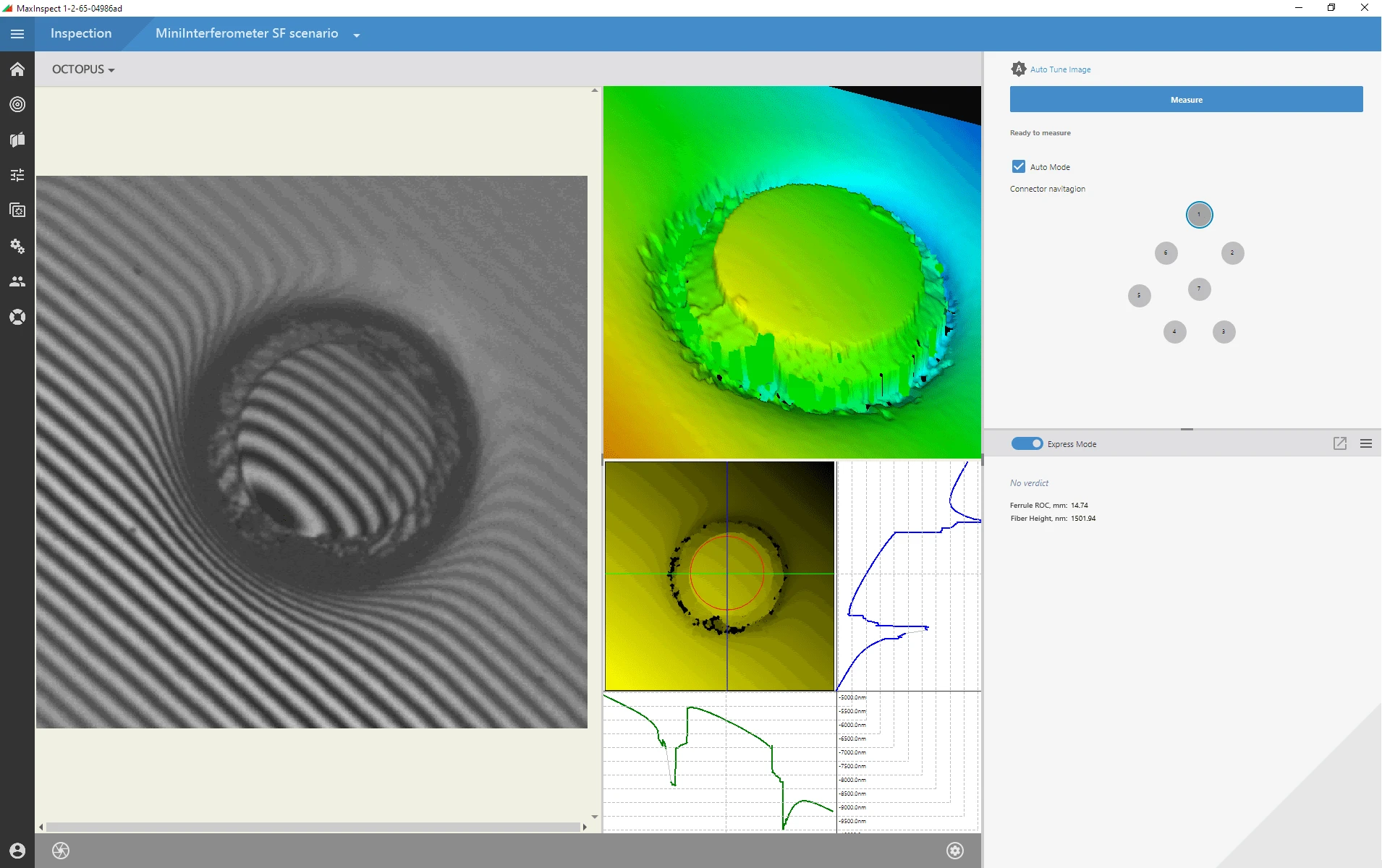

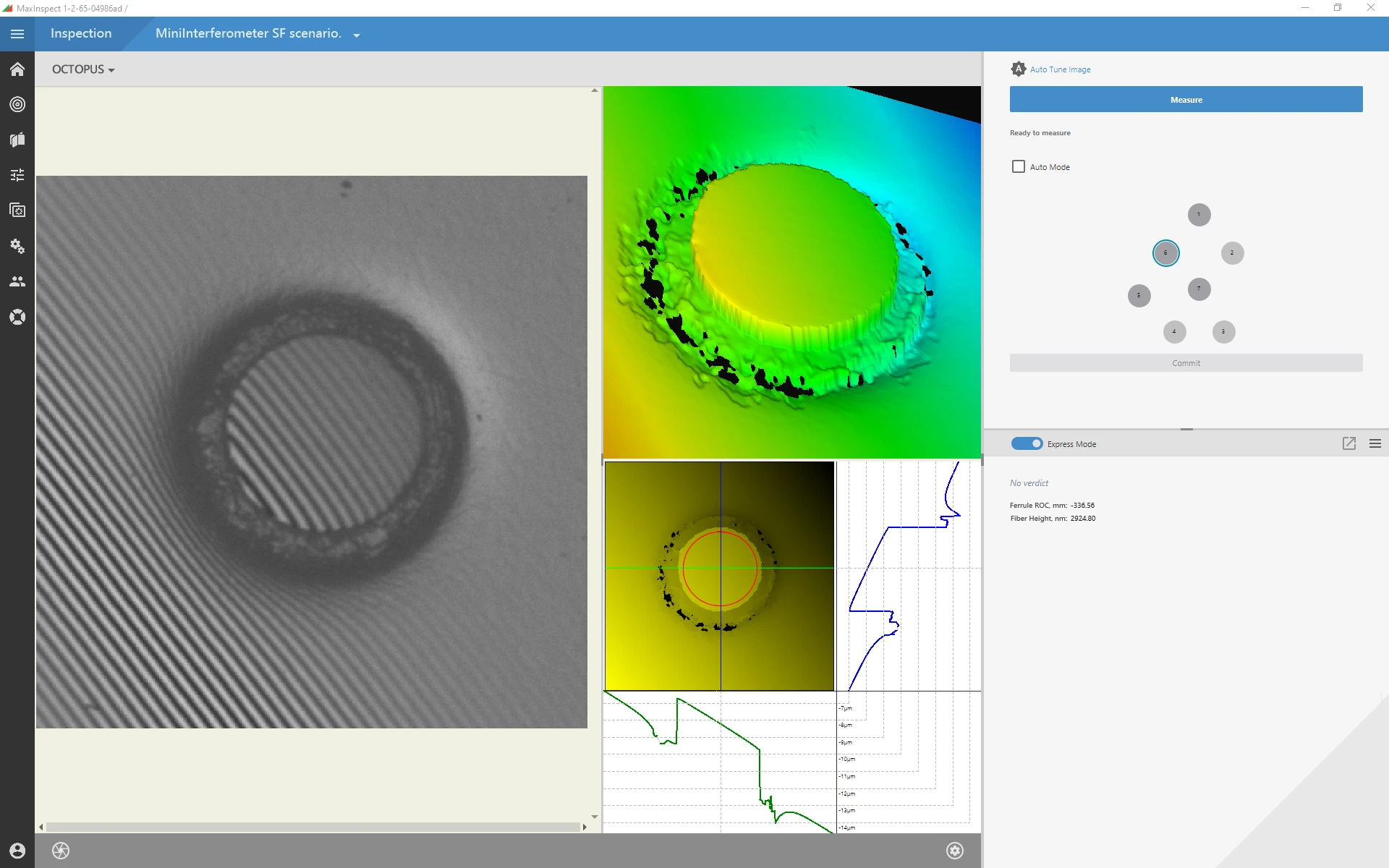

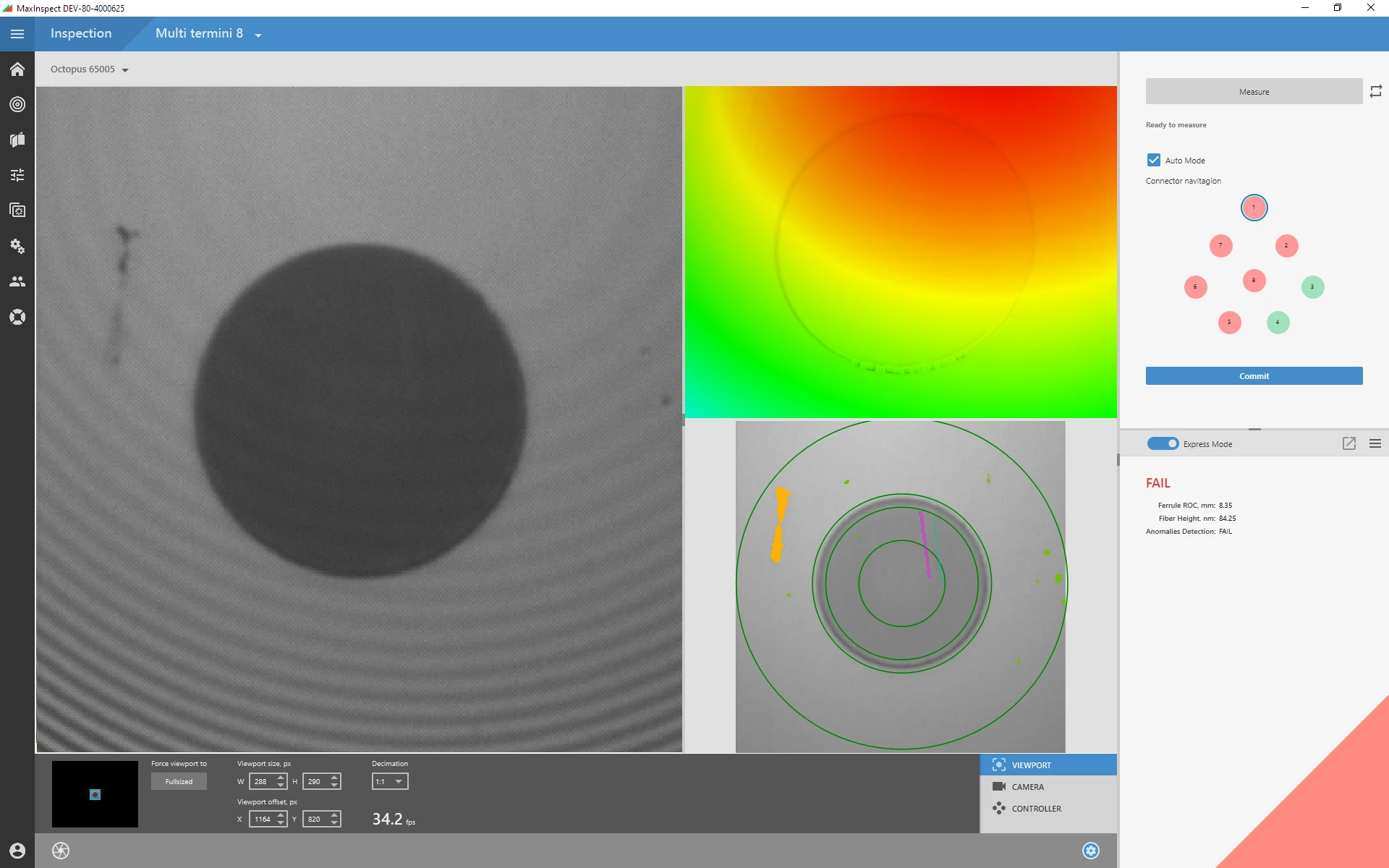

Inspection of a multi-termini MIL-DTL-38999 connector: Express Report for one of the termini.

Inspection of a multi-termini MIL-DTL-38999 connector: Express Report for one of the termini.

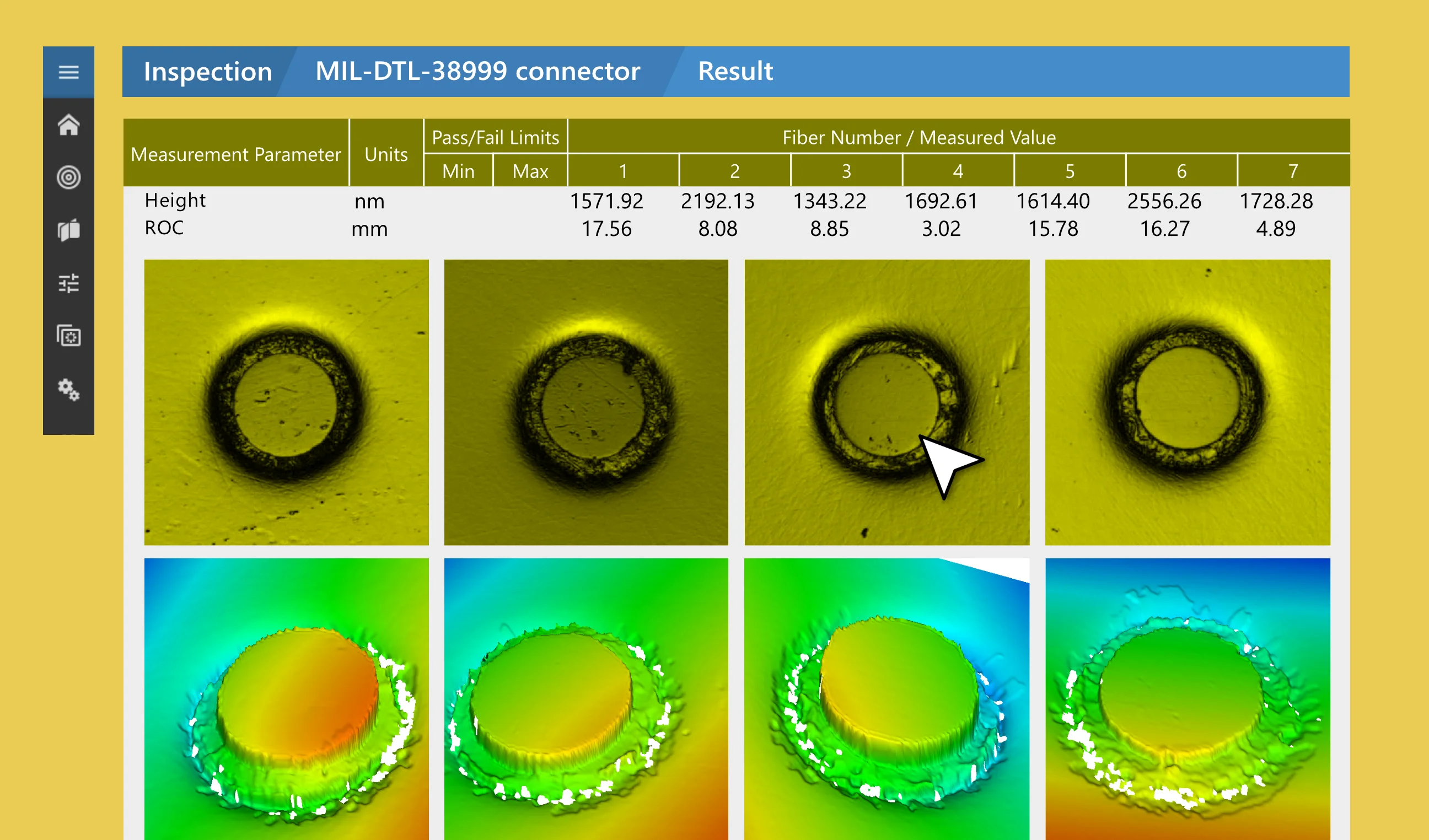

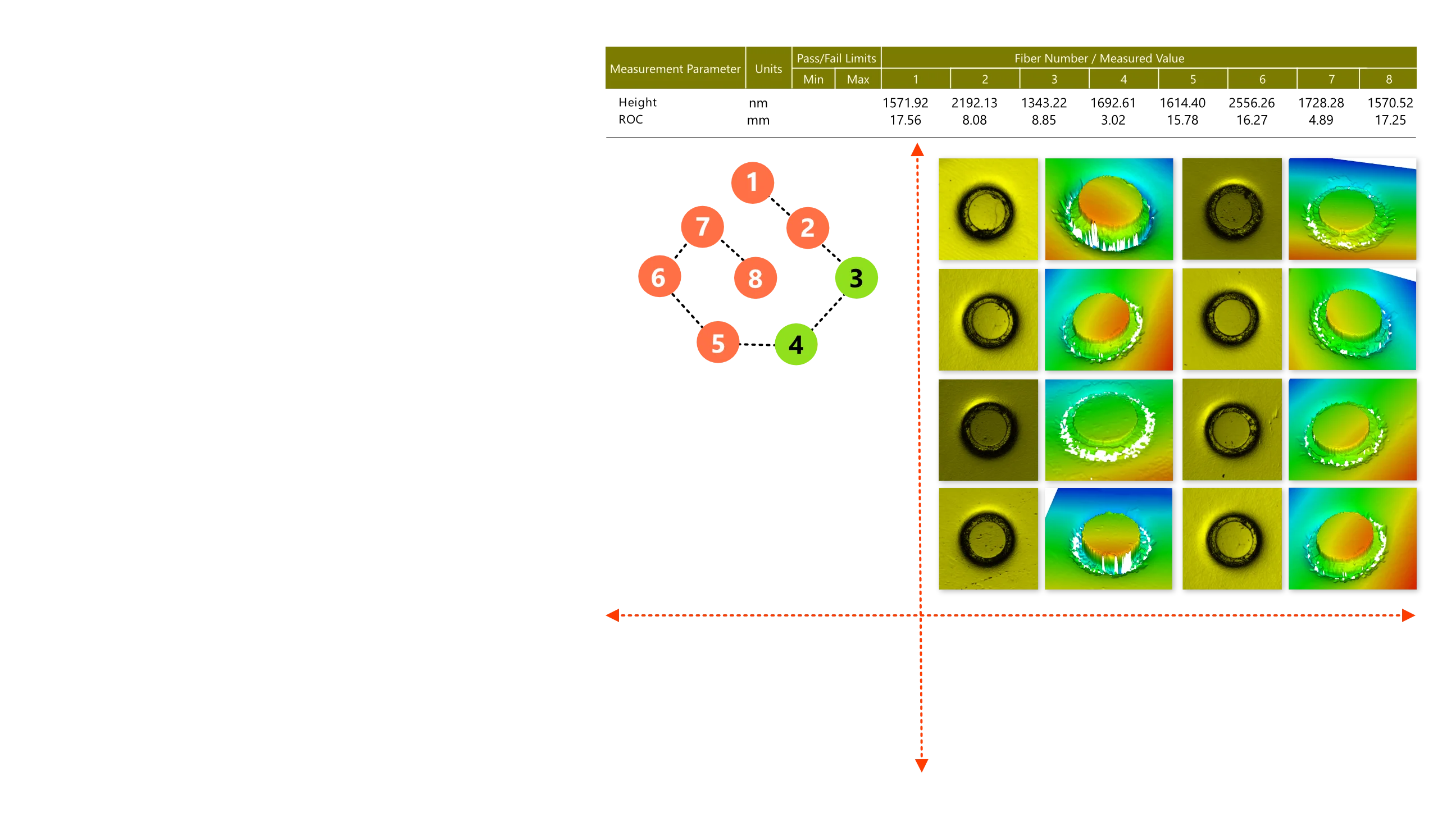

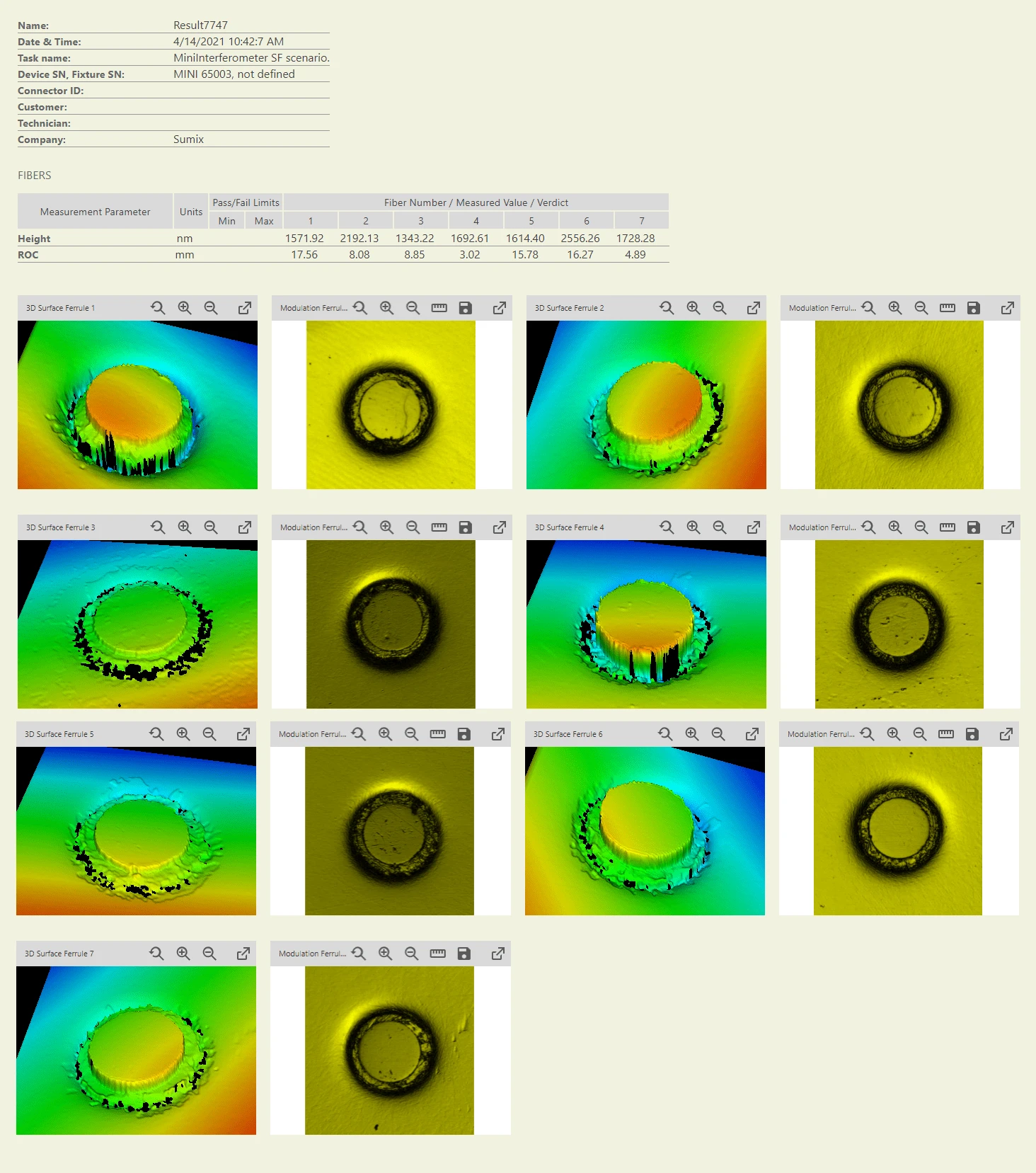

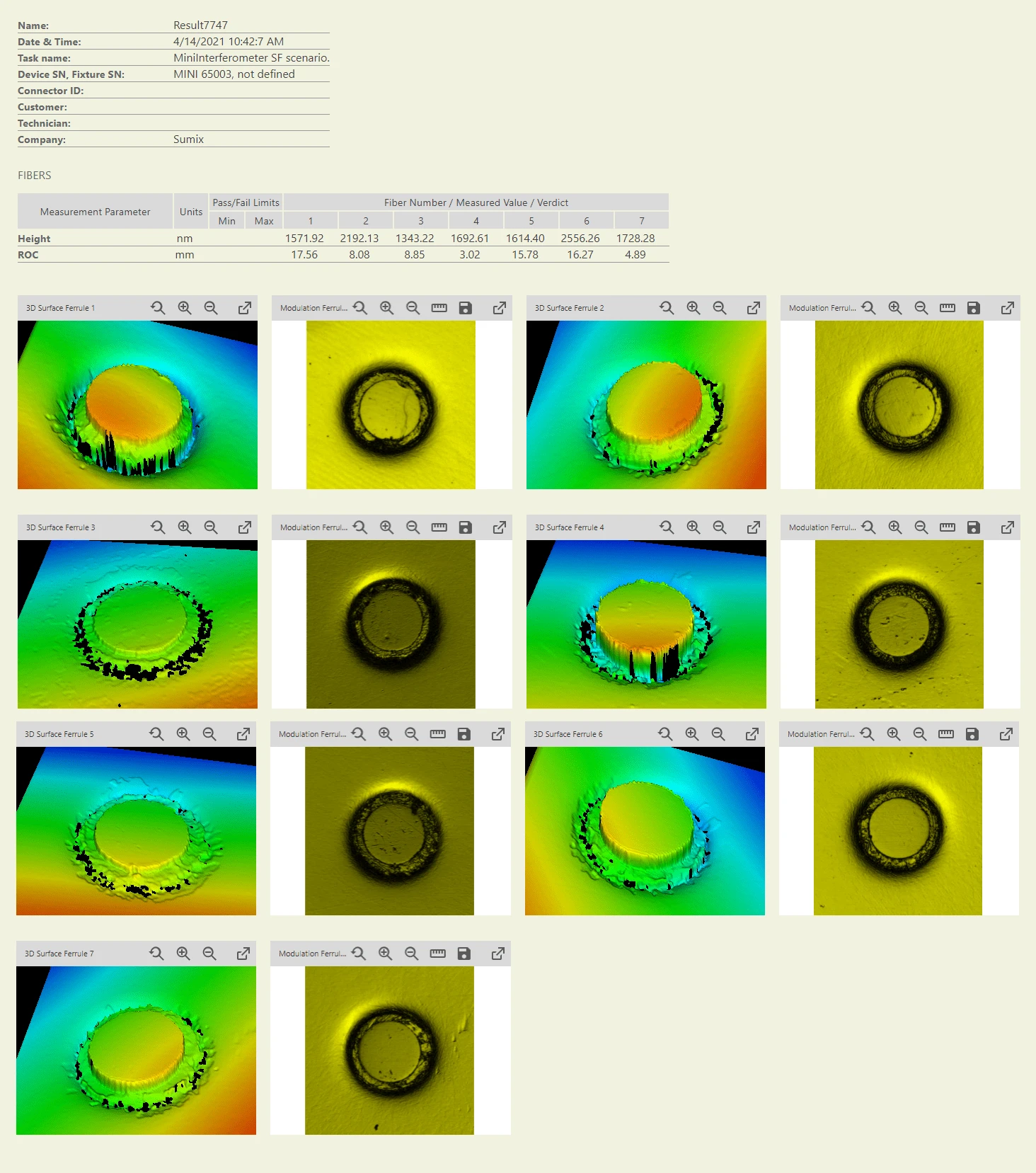

Full report for a MIL-DTL-38999 connector: 3D images and geometry parameters.

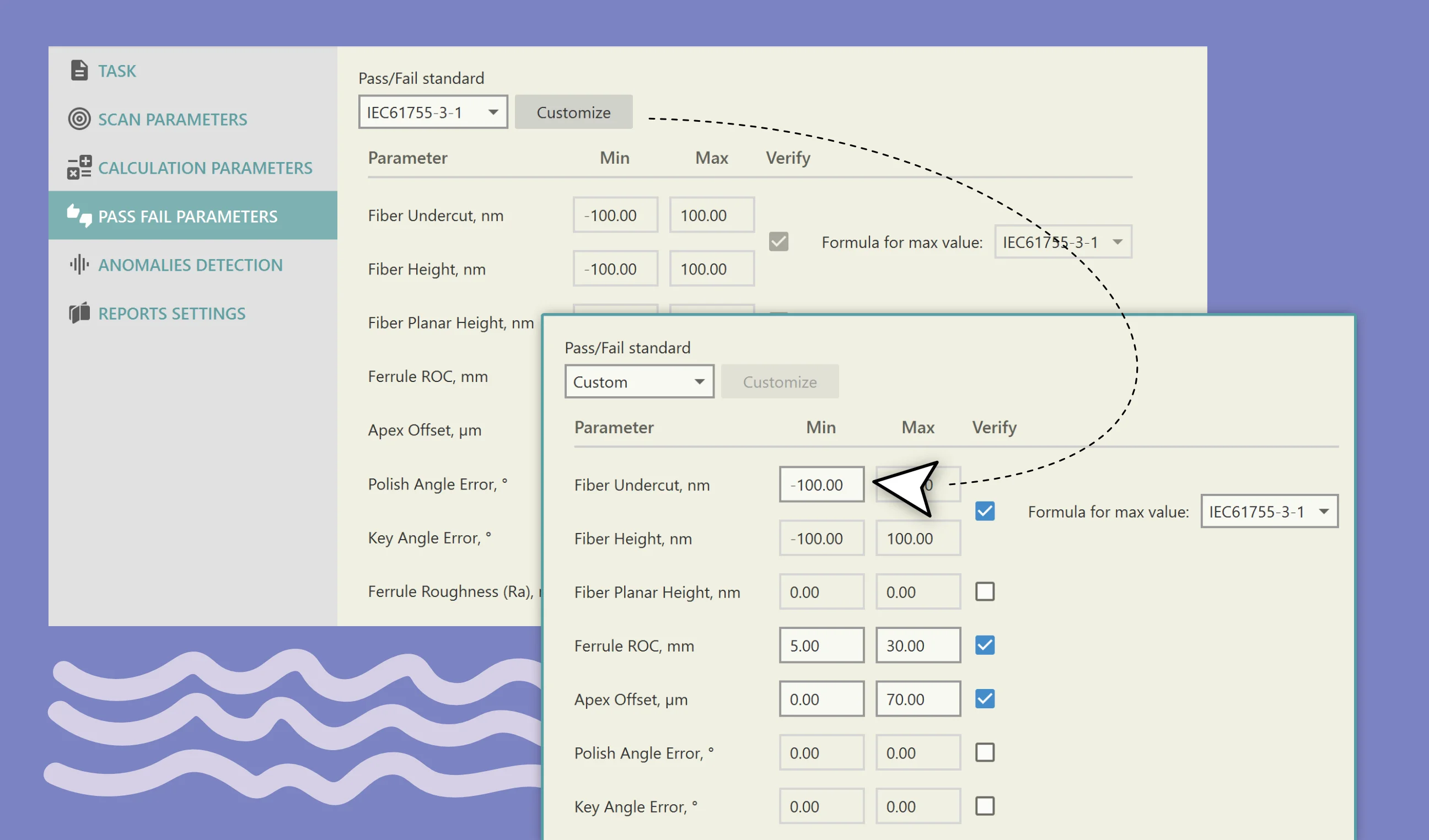

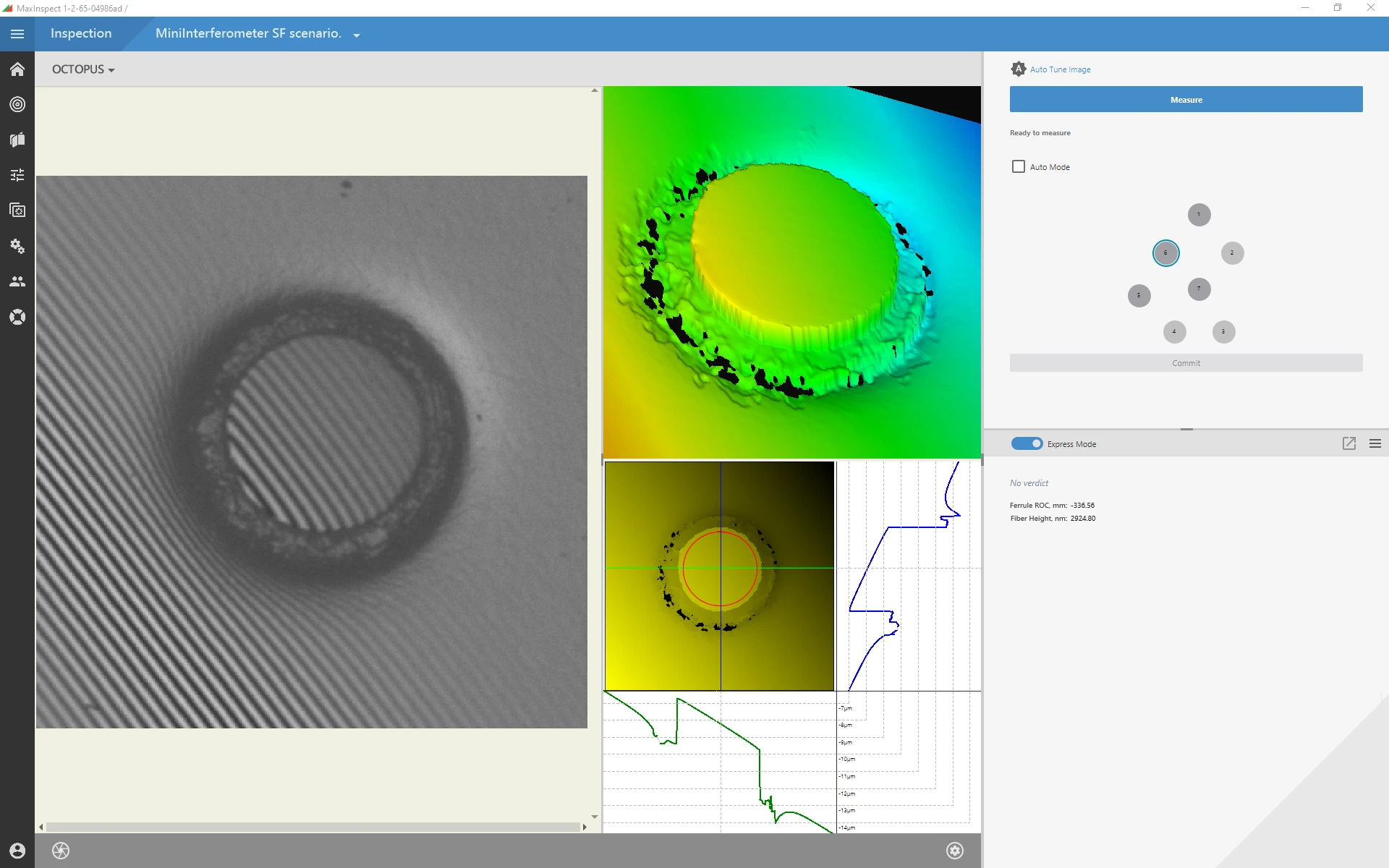

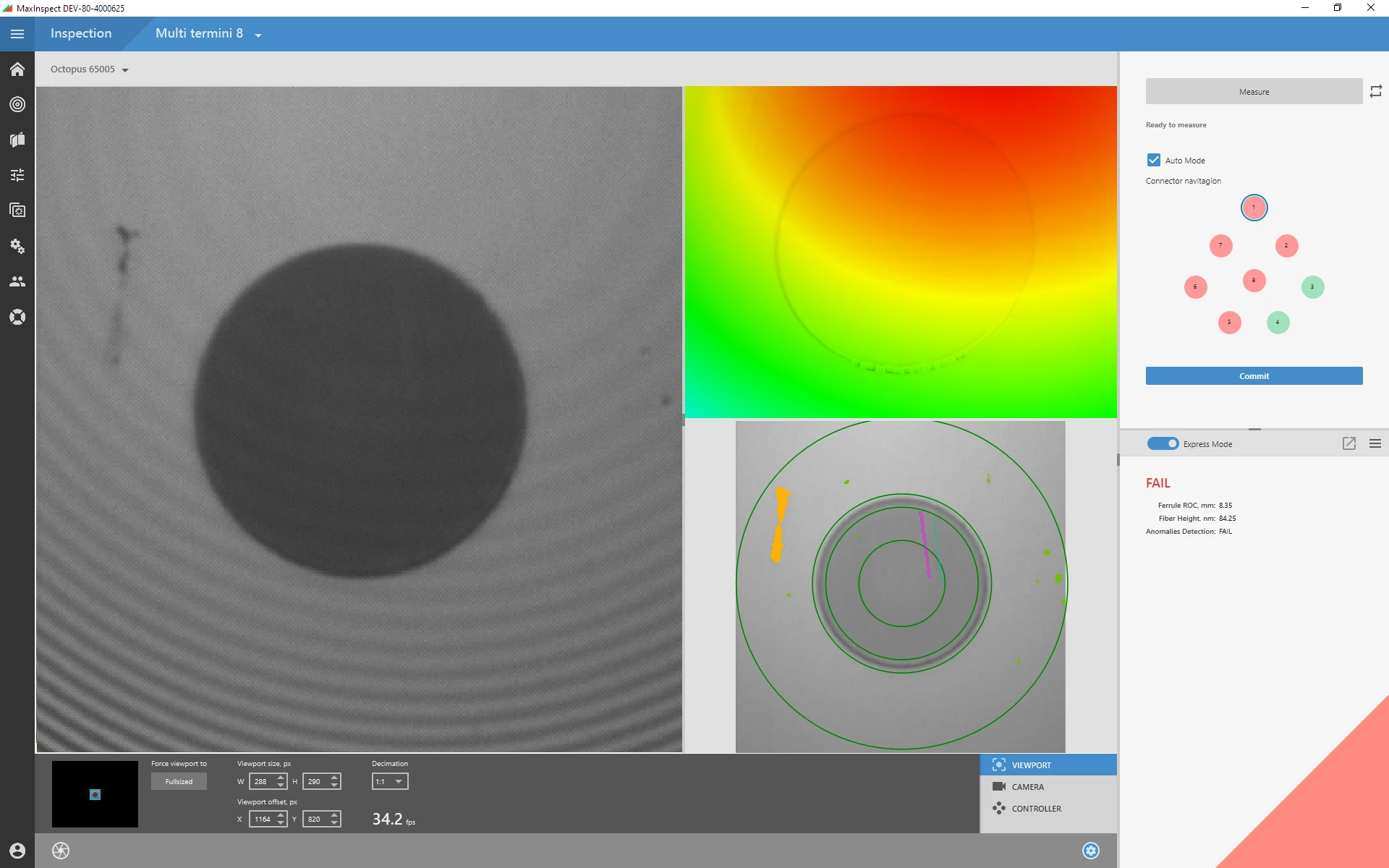

Inspection of a multi-termini MIL-DTL-38999 connector: Anomalies detection and geometry report.

Specification

System

Measurement

3 sec for MT12,

6.9 sec for MT16,

4.9 sec for MT24,

5.7 sec for MT72.

Apex offset (µm): 0 to 2000

Fiber height4 (μm): more than 10005

Angles measurements - full range (degrees): 0 to 286

Fiber Height: 0.8 nm (MT12); 0.1 nm (SC/PC)

Angles: 0.005 deg (MT12); 0.0002 deg (SC/PC)

Apex Offset: 0.04 µm (SC/PC)

Fiber Height: 1.1 nm (MT12); 0.4 nm (SC/PC)

Angles: 0.01 deg (MT12); 0.006 deg (SC/PC)

Apex Offset: 1.1 µm (SC/PC)

Recommended Environment

Dimensions and Weight

Power

System Requirements

- Windows 10, Windows 11

- Intel Core i7

- 4GB RAM or higher

- Built-in Intel USB 3.0 controller

- Microsoft Excel 2010 or higher

- Measurement time may vary depending on computer performance and connector end face shape.

- Values were calculated from 30 consecutive measurements without interaction on connector between measurements (connector fixed) and represent one sigma value.

- Values were calculated from 30 consecutive measurements with removing and inserting connector between measurements (connector reloaded) and represent one sigma value.

- Difference from the highest and lowest points of the scanned object.

- <100 µm available by default. >100 µm - for special connectors/tasks (software adjustment required).

- Regular fixtures: 0, 8, 9 degrees. Customized fixtures: 0 - 28 degrees.

Kit Contents

OCTOPUS 2 interferometric system includes:

- OCTOPUS 2 interferometer

- USB 3.0 cable

- AC adapter

- Stand

- Case

- MaxInspect™ software license

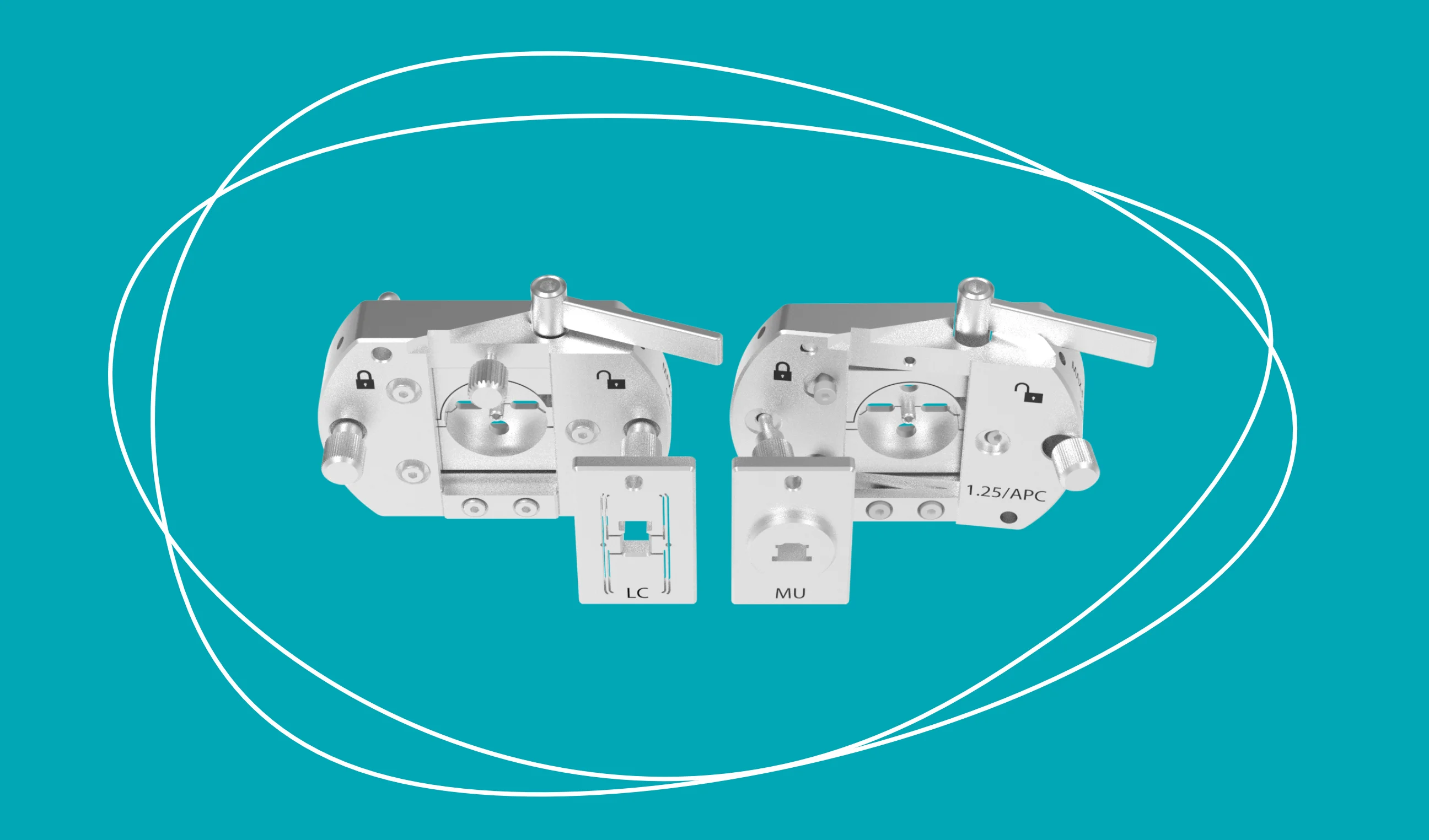

Fixtures and other accessories should be ordered separately.

Adapters should be ordered separately. The current range of available adapters includes the adapters for inspection of:

- MIL-DTL-38999 connector, Series III, shell size 15, receptacle, socket insert and pin insert;

- MIL-DTL-38999 connector, Series III, shell size 25, receptacle, socket insert and pin insert;

- MIL-DTL-38999 connector, Series III, shell size 25, plug, socket insert and pin insert.

Other adapters can be added upon customer’s request.

Annual Software Maintenance and Support Plan

Purchased with an interferometer

(i) e-mail support for all technical issues relating to the use of the interferometer and the MaxInspect software within one business day of receipt;

(ii) all revisions and updates to the MaxInspect software;

(iii) remote hardware and software demonstration, help desk and video tutorials;

(iv) remote hardware troubleshooting;

(v) providing a loaner unit for the period of repair or calibration (upon availability and if requested).

Extending the Support Plan is optional. If the Support Plan is extended for next year continuously (without a break in support), a 50% discount for the Support Plan applies.

Samples

Inspection of a multi-termini MIL-DTL-38999 connector: Express Report for one of the termini.

Inspection of a multi-termini MIL-DTL-38999 connector: Express Report for one of the termini.

Full report for a MIL-DTL-38999 connector: 3D images and geometry parameters.

Inspection of a multi-termini MIL-DTL-38999 connector: Anomalies detection and geometry report.

E2000 is a trademark of Diamond SA.

MTP is a registered trademark of US Conec Ltd.

CS is a registered trademark of Senko Advanced Components Inc.