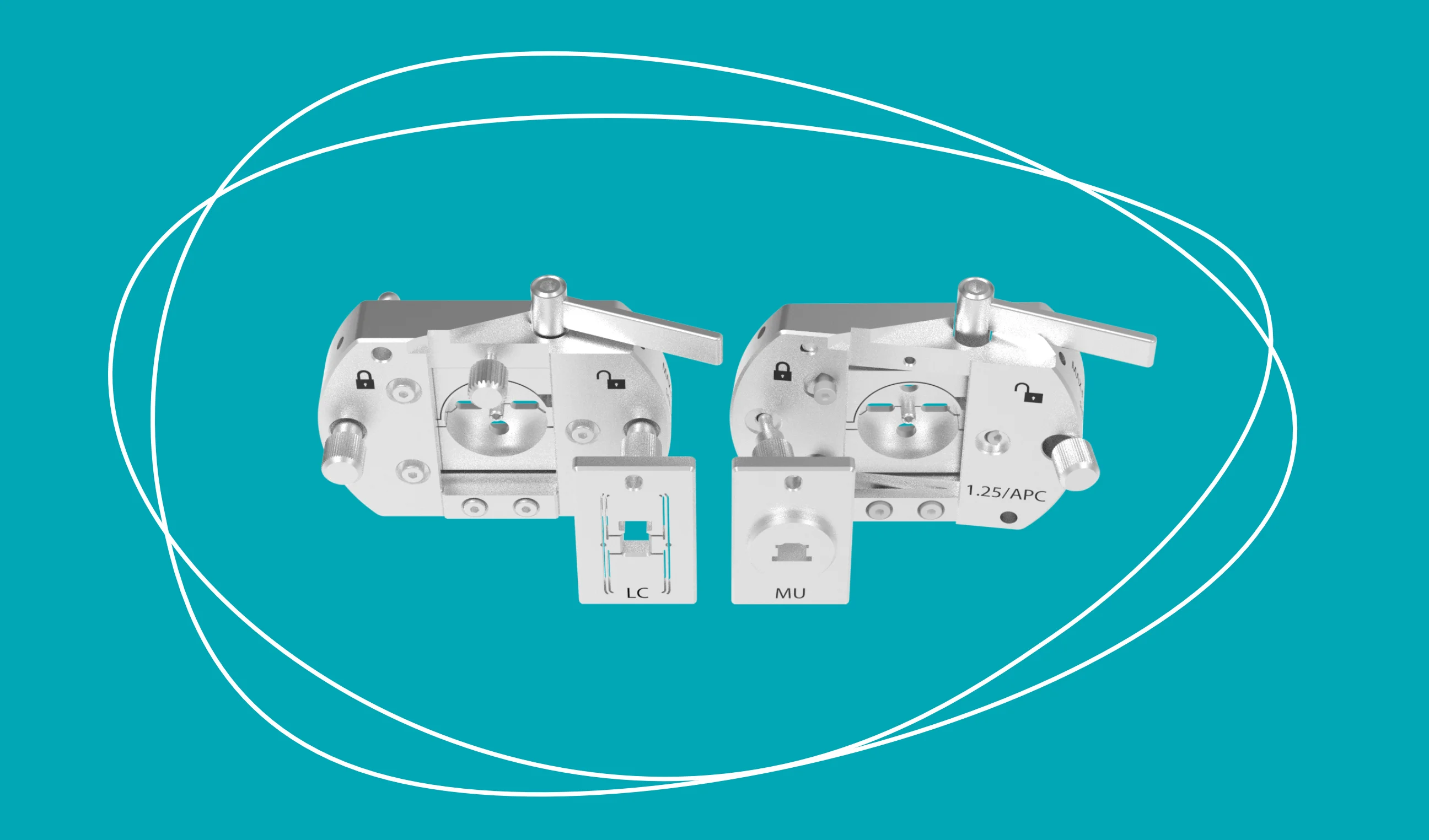

MAX-QM+ is an automated interferometer for inspection of single and multi-fiber connectors of MTP®/MPO, ST, FC, SC, LC, MU, E2000™, SMA types as well as MT, MT-RJ ferrules.

High measurement speed, portable design, autofocus and a large field of view with the ability to test 12 or 16 fibers per row have made MAX-QM+ an immensely popular solution for high-volume production lines.

MAX-QM+

for inspection of single and multi-fiber connectors.

Popular solution for high-volume production lines

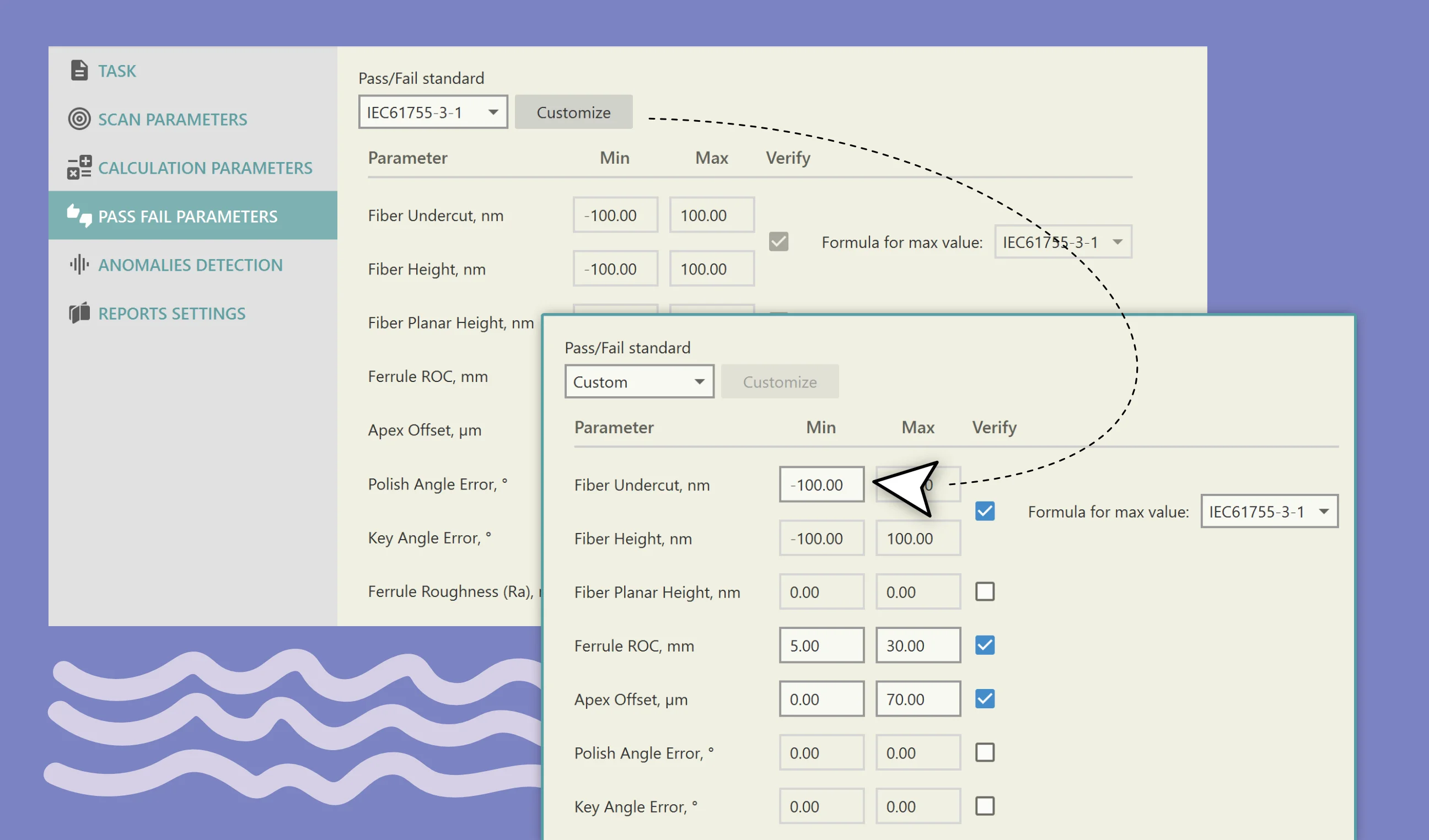

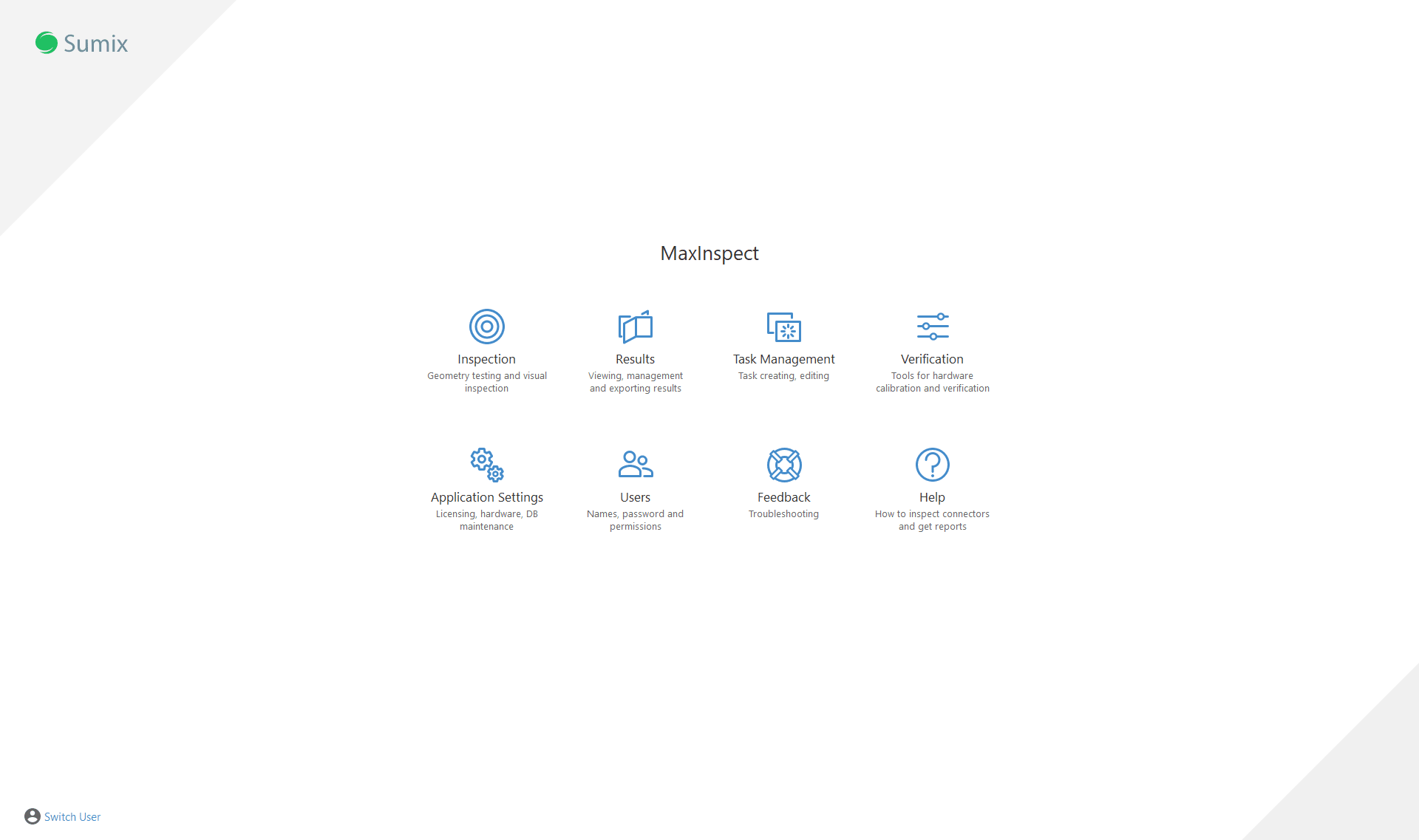

™ Software

™ Software

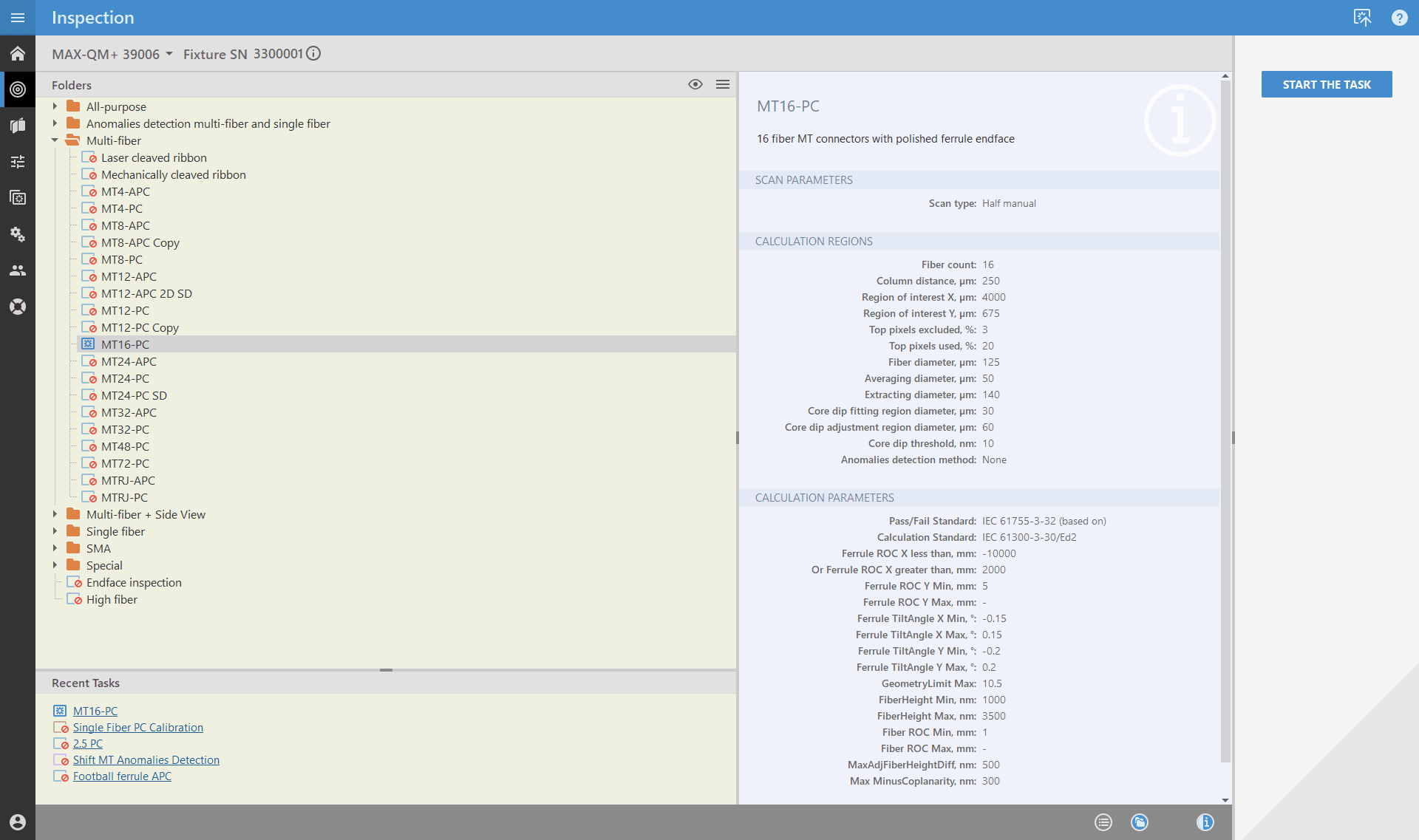

Start screen

Variety of tasks for all major connector types per IEC/Telcordia industry standards. You may choose to see only active tasks supported by your equipment.

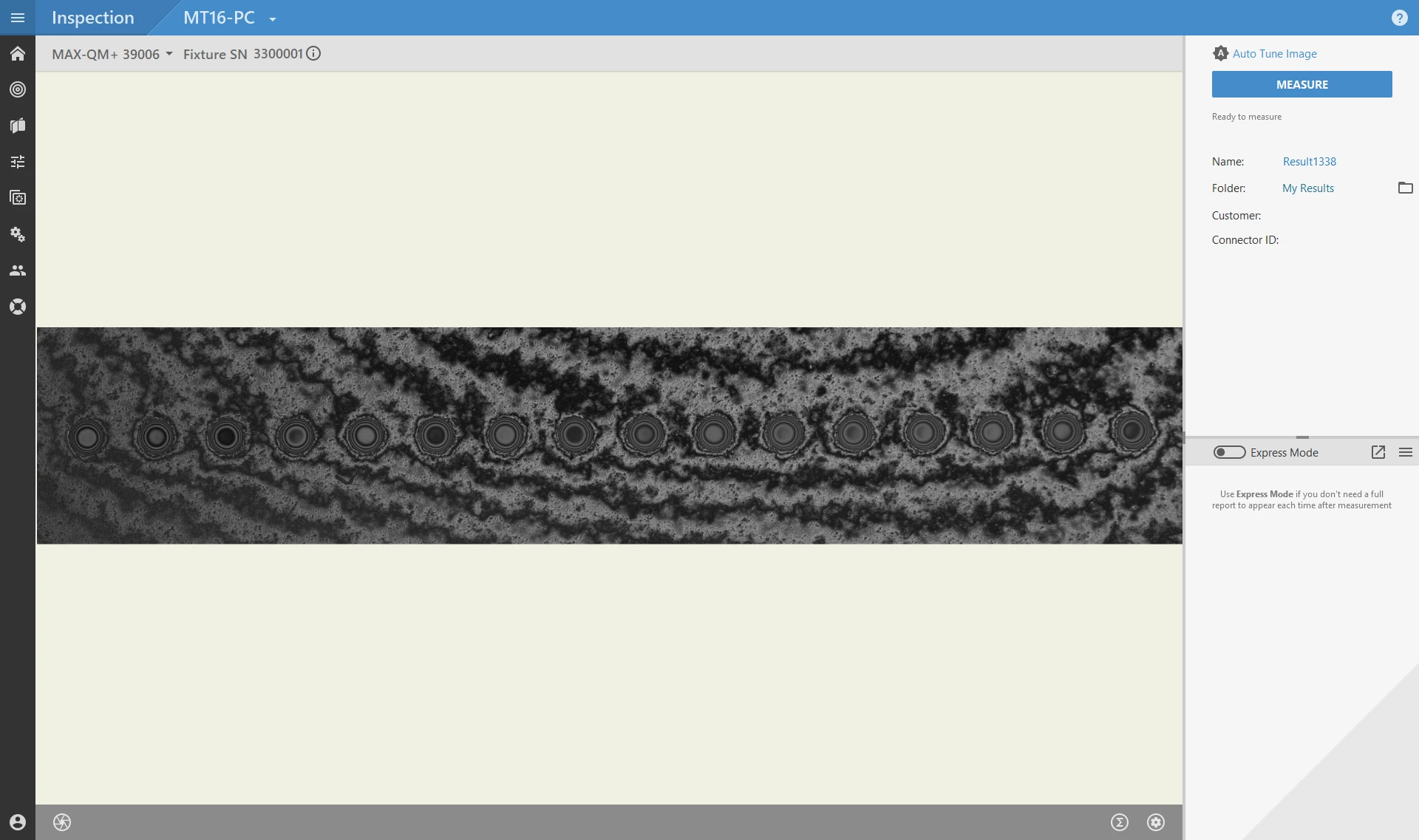

Just press Measure to get the connector focused and measured within several seconds.

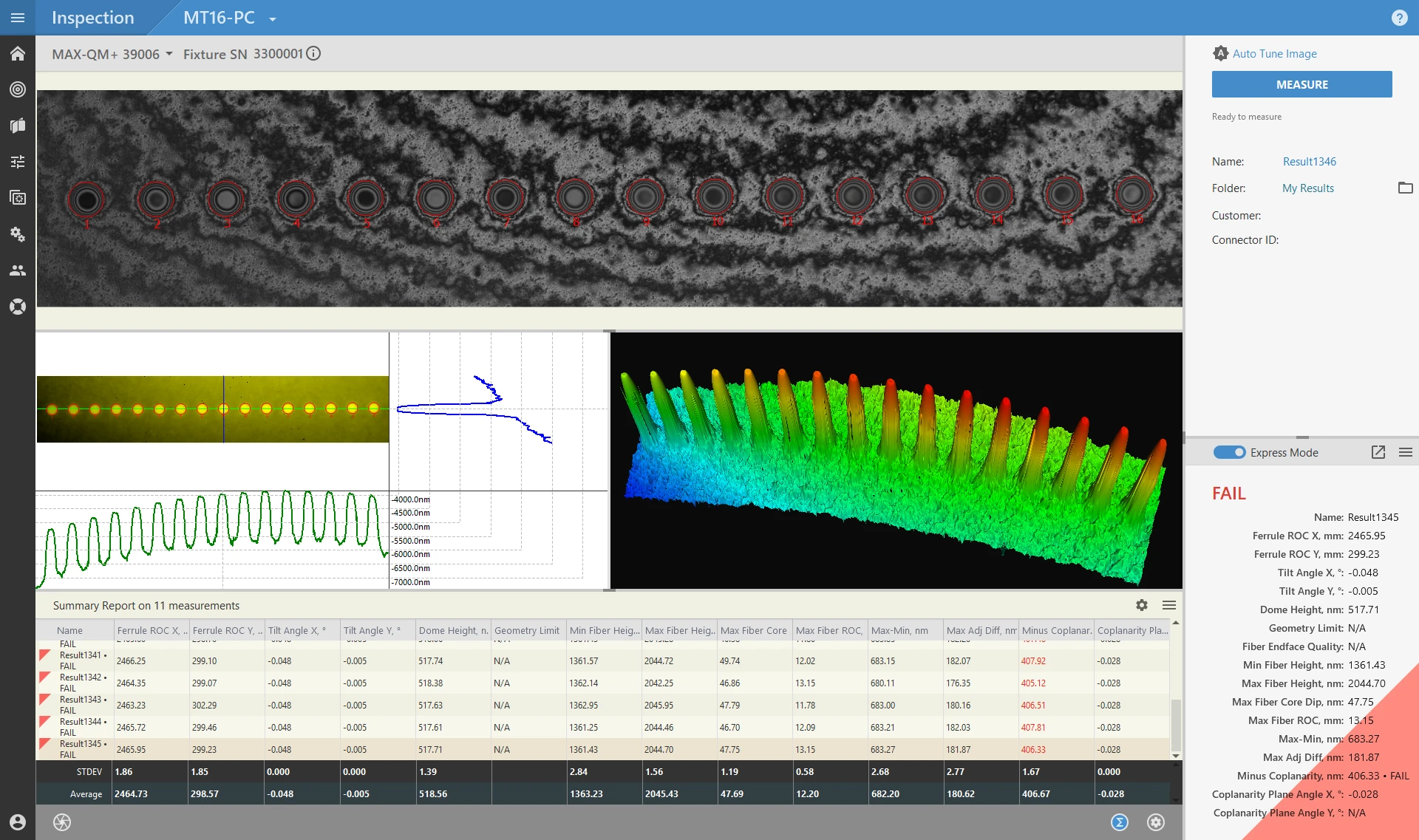

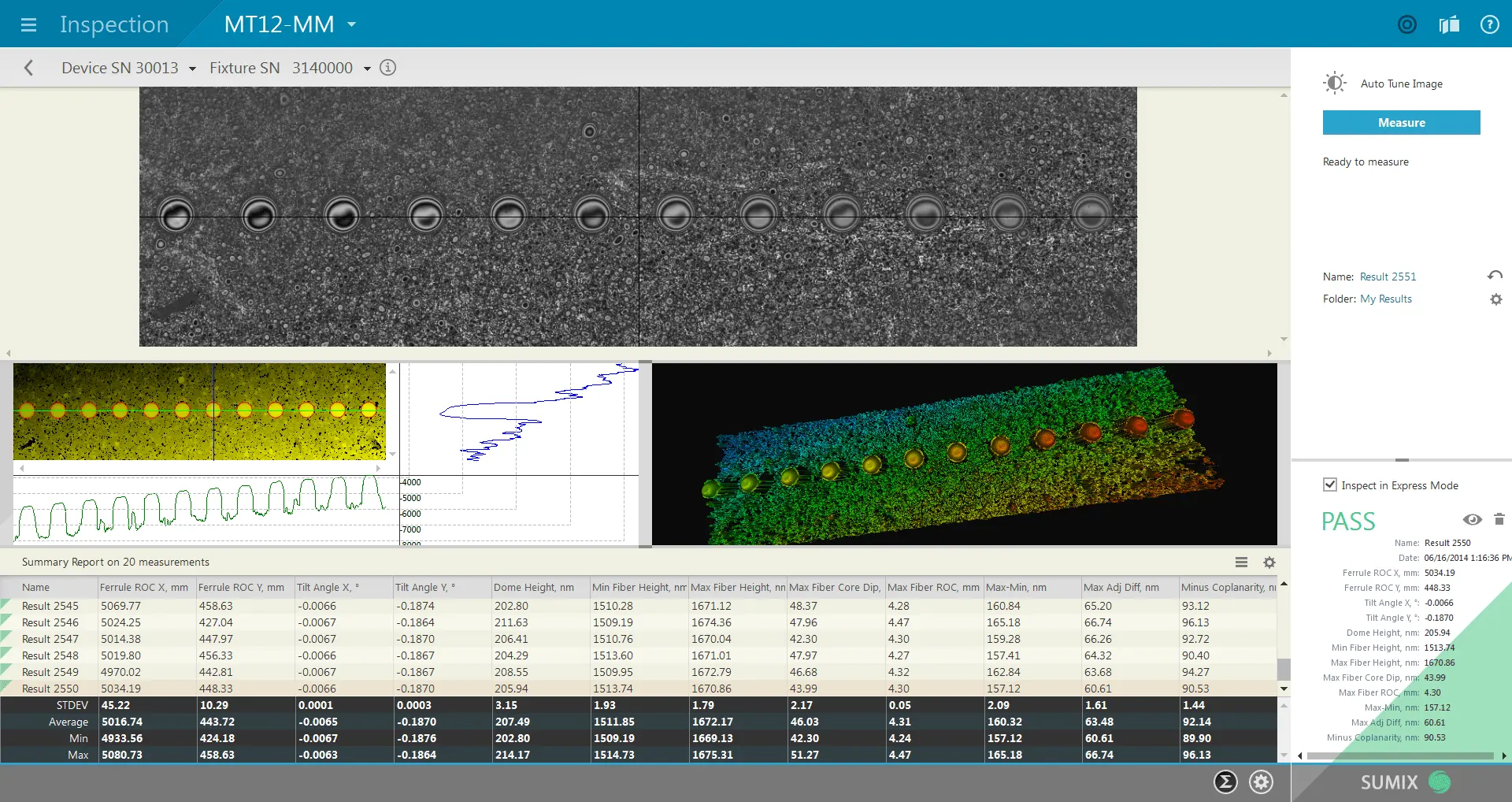

Use Express mode for testing large number of connectors. Check the test result on the same screen and proceed to the next connector.

You may open the Summary Report panel to see real-time statistics.

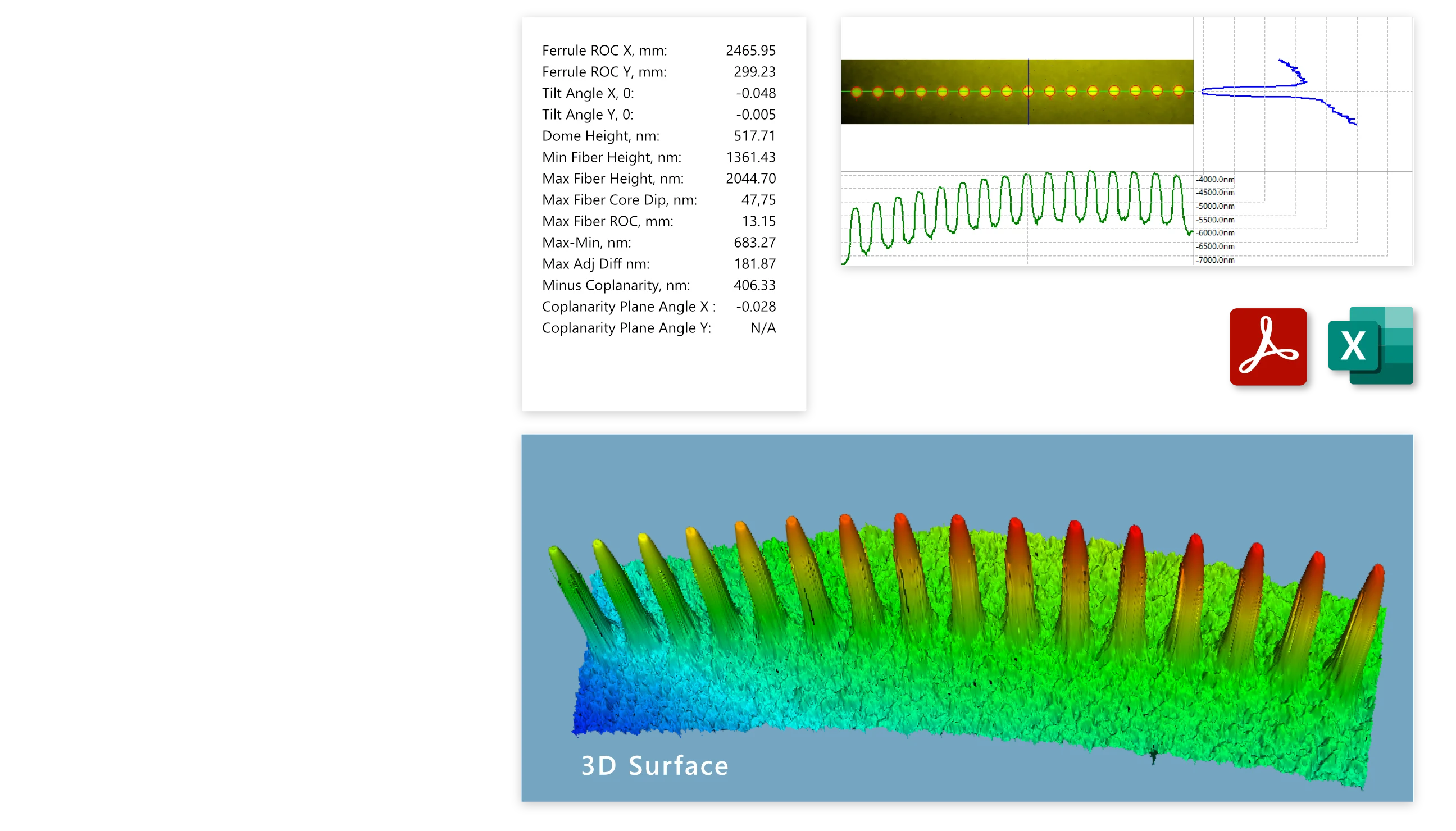

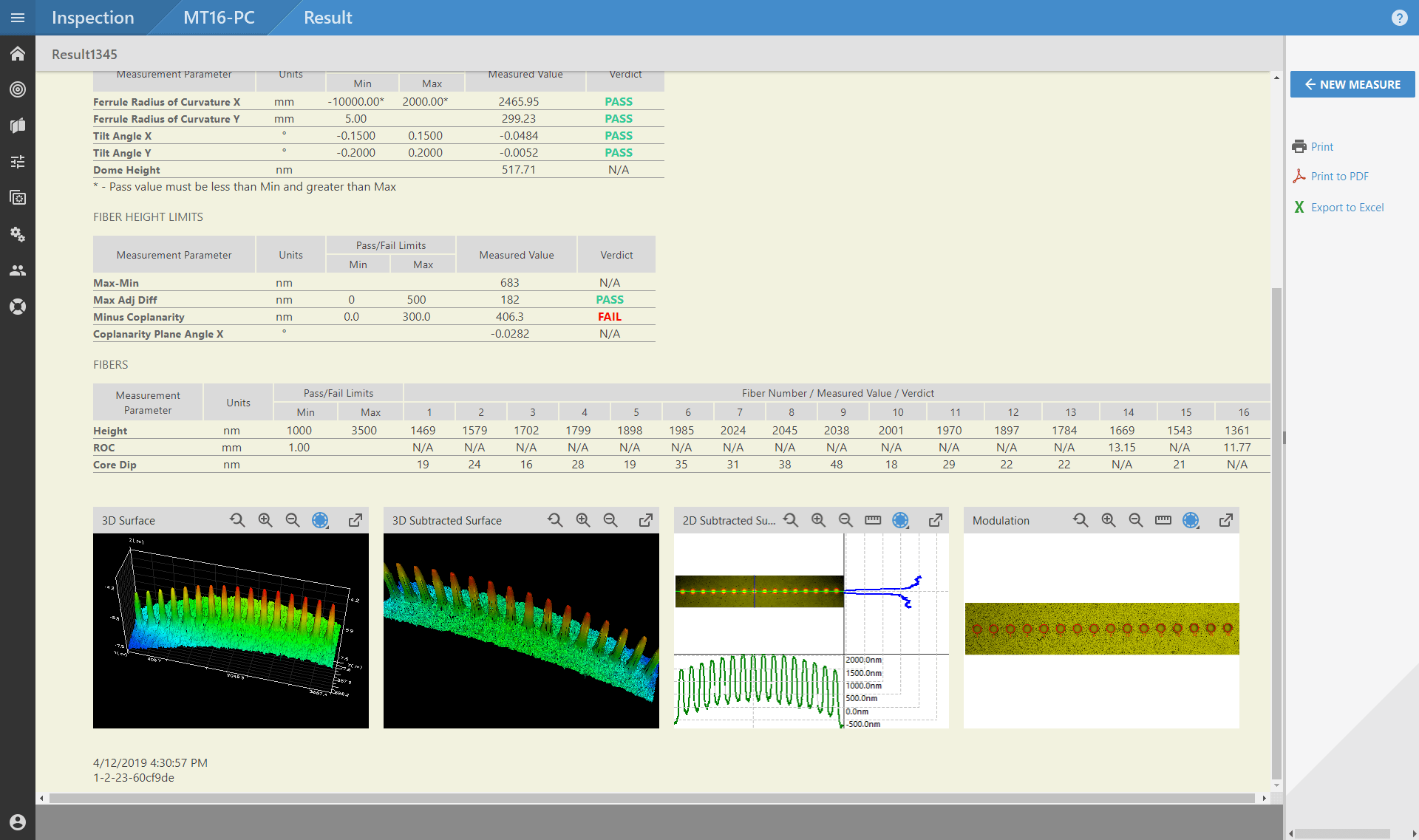

Full Report contains measured geometry parameters. Print or export the report to certify your connector.

Full Report (continued).

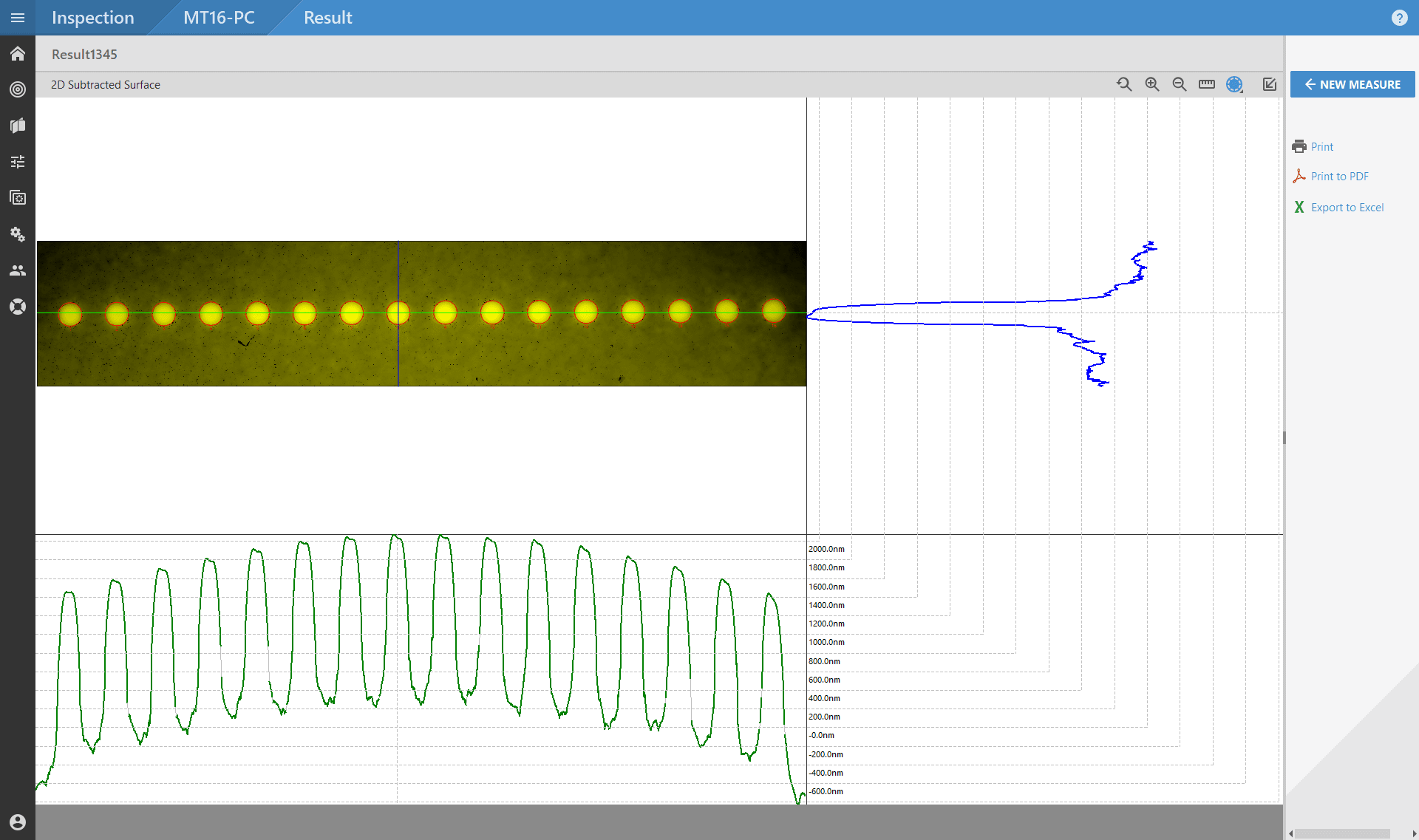

Zoomed 2D subtracted image in report

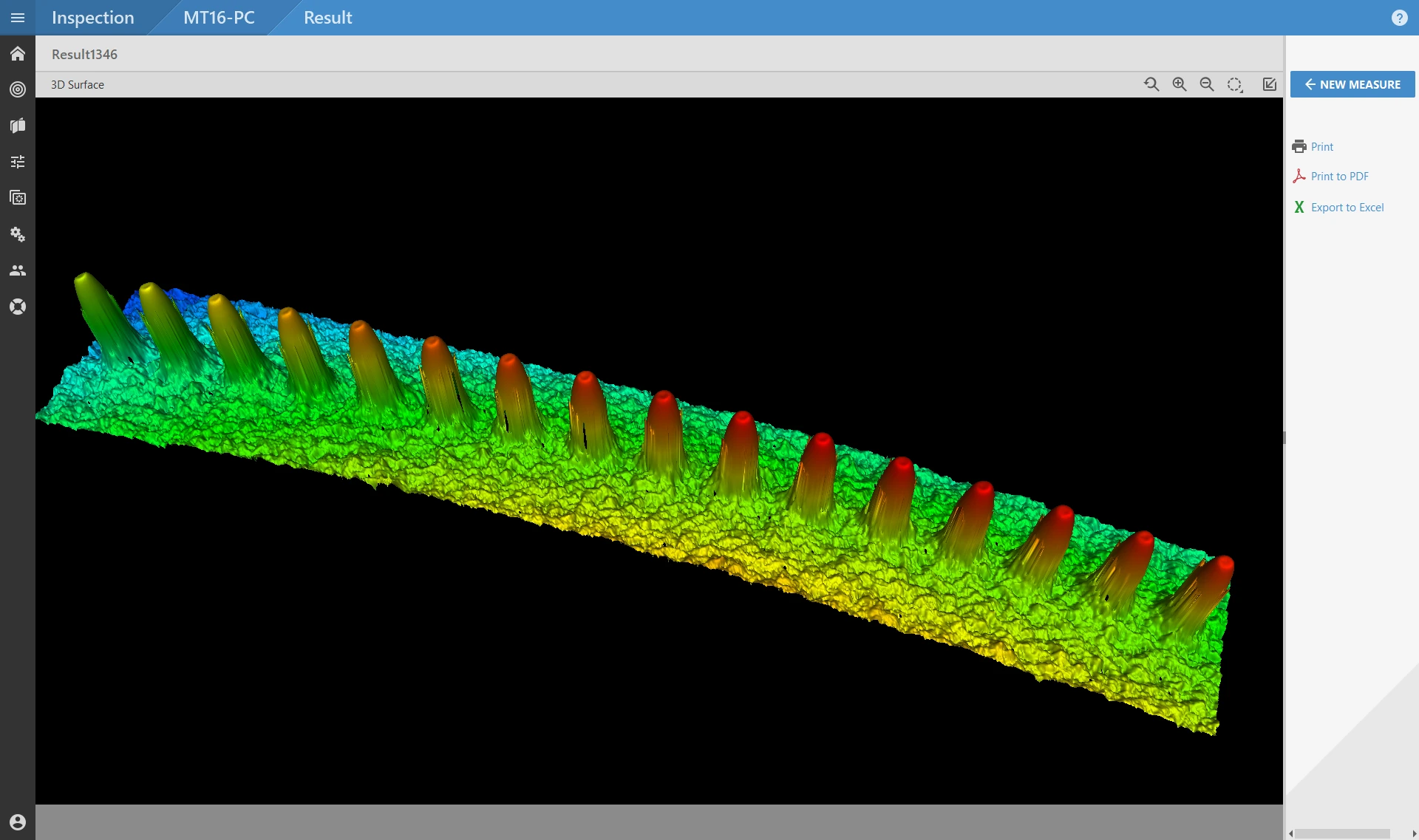

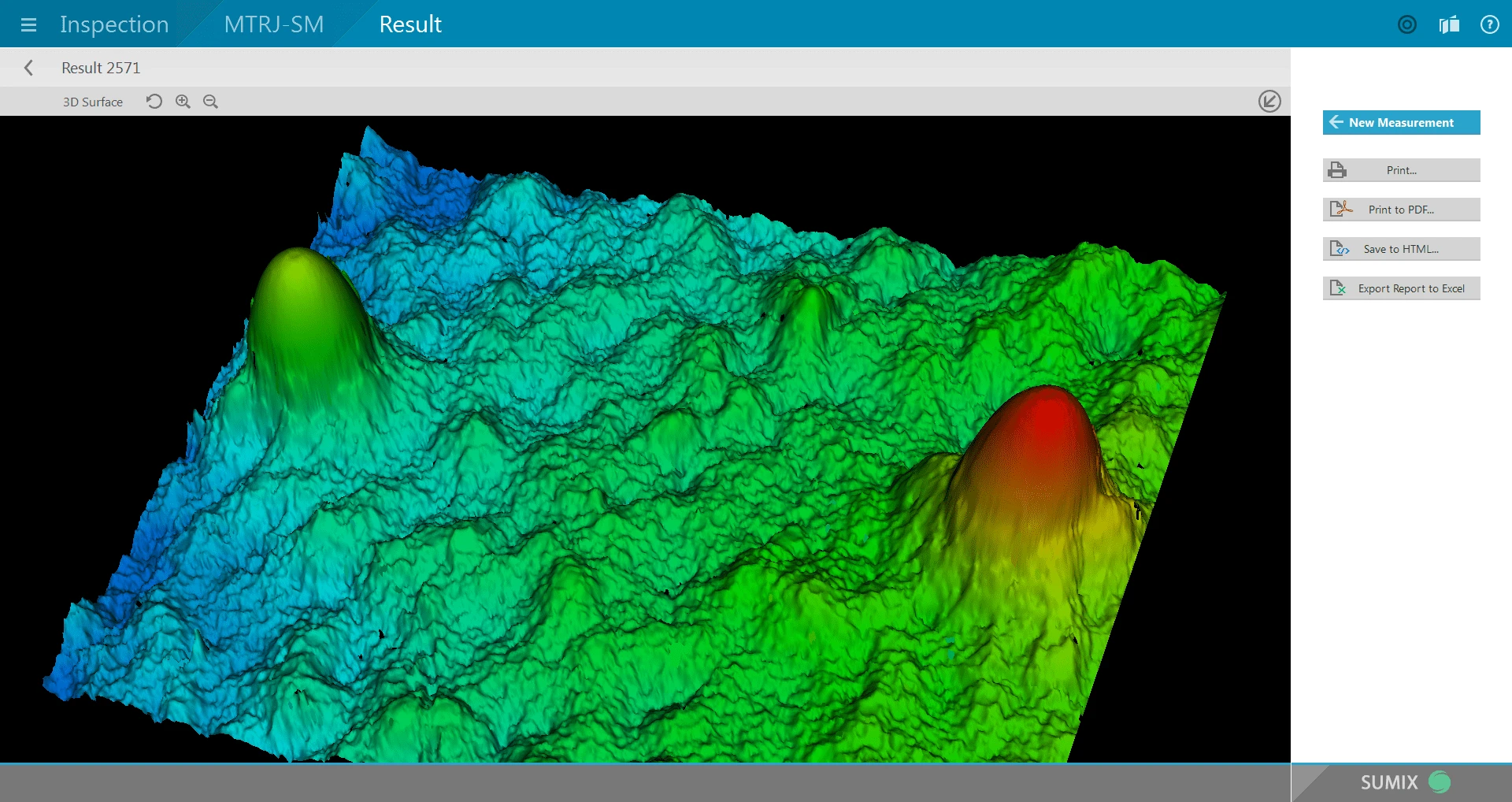

Zoomed 3D surface in report

Specification

System

Measurement

3 sec for MT12,

6.9 sec for MT16,

4.9 sec for MT24,

5.7 sec for MT72.

Apex offset (µm): 0 to 2000

Fiber height4 (μm): more than 10005

Angles measurements - full range (degrees): 0 to 286

Fiber Height: 0.8 nm (MT12); 0.1 nm (SC/PC)

Angles: 0.005 deg (MT12); 0.0002 deg (SC/PC)

Apex Offset: 0.04 µm (SC/PC)

Fiber Height: 1.1 nm (MT12); 0.4 nm (SC/PC)

Angles: 0.01 deg (MT12); 0.006 deg (SC/PC)

Apex Offset: 1.1 µm (SC/PC)

Recommended Environment

Dimensions and Weight

Power

System Requirements

- Windows 10, Windows 11

- Intel Core i7

- 4GB RAM or higher

- Built-in Intel USB 3.0 controller

- Microsoft Excel 2010 or higher

- Measurement time may vary depending on computer performance and connector end face shape.

- Values were calculated from 30 consecutive measurements without interaction on connector between measurements (connector fixed) and represent one sigma value.

- Values were calculated from 30 consecutive measurements with removing and inserting connector between measurements (connector reloaded) and represent one sigma value.

- Difference from the highest and lowest points of the scanned object.

- <100 µm available by default. >100 µm - for special connectors/tasks (software adjustment required).

- Regular fixtures: 0, 8, 9 degrees. Customized fixtures: 0 - 28 degrees.

Kit Contents

MAX-QM+ interferometric system includes:

- MAX-QM+ interferometer

- USB 3.0 cable

- AC adapter

- Allen key

- Optical flat standard for device verification

- Case

- MaxInspect™ software license

Fixtures and other accessories should be ordered separately.

Annual Software Maintenance and Support Plan

Purchased with an interferometer

(i) e-mail support for all technical issues relating to the use of the interferometer and the MaxInspect software within one business day of receipt;

(ii) all revisions and updates to the MaxInspect software;

(iii) remote hardware and software demonstration, help desk and video tutorials;

(iv) remote hardware troubleshooting;

(v) providing a loaner unit for the period of repair or calibration (upon availability and if requested).

Extending the Support Plan is optional. If the Support Plan is extended for next year continuously (without a break in support), a 50% discount for the Support Plan applies.

Samples

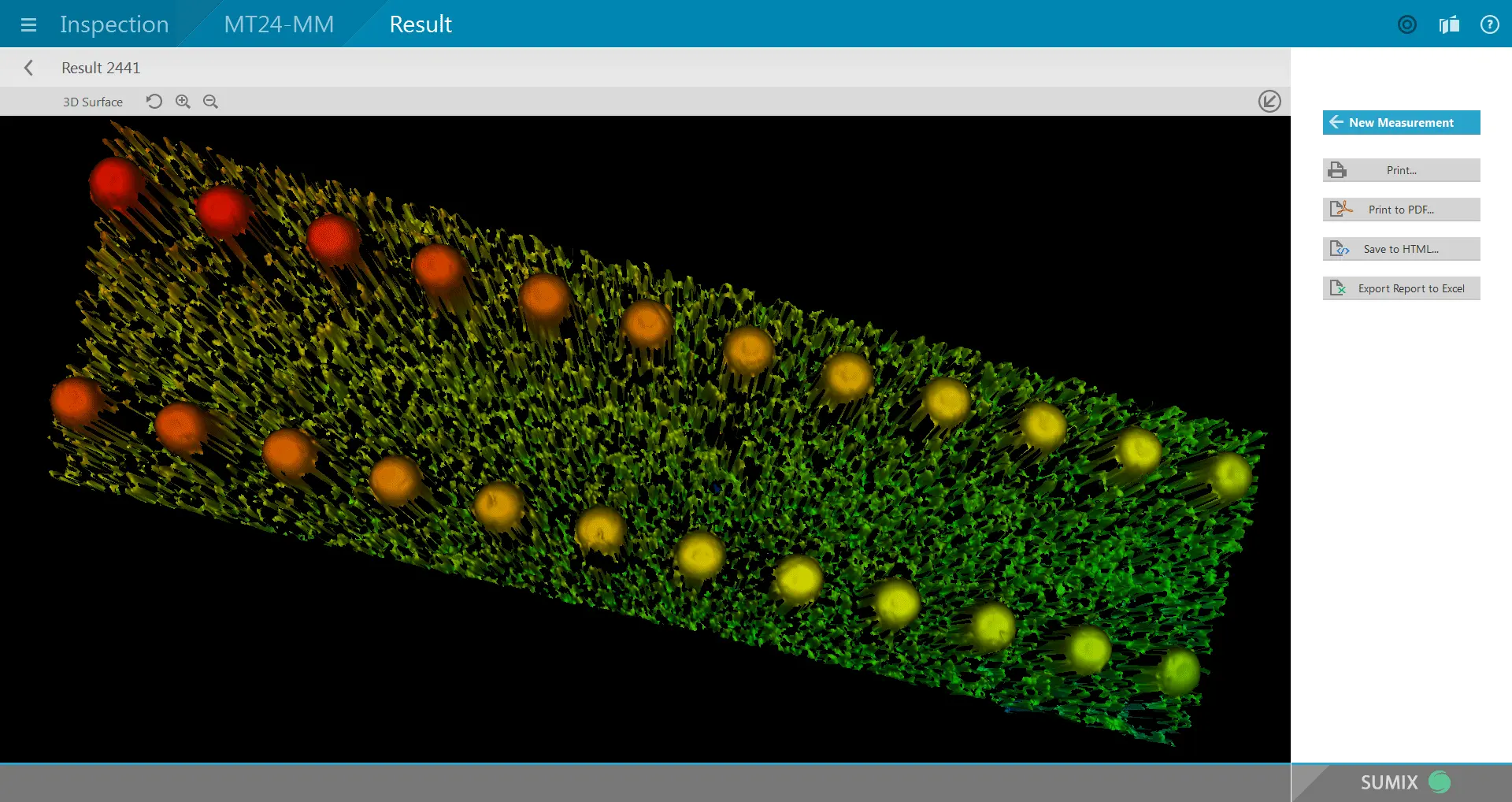

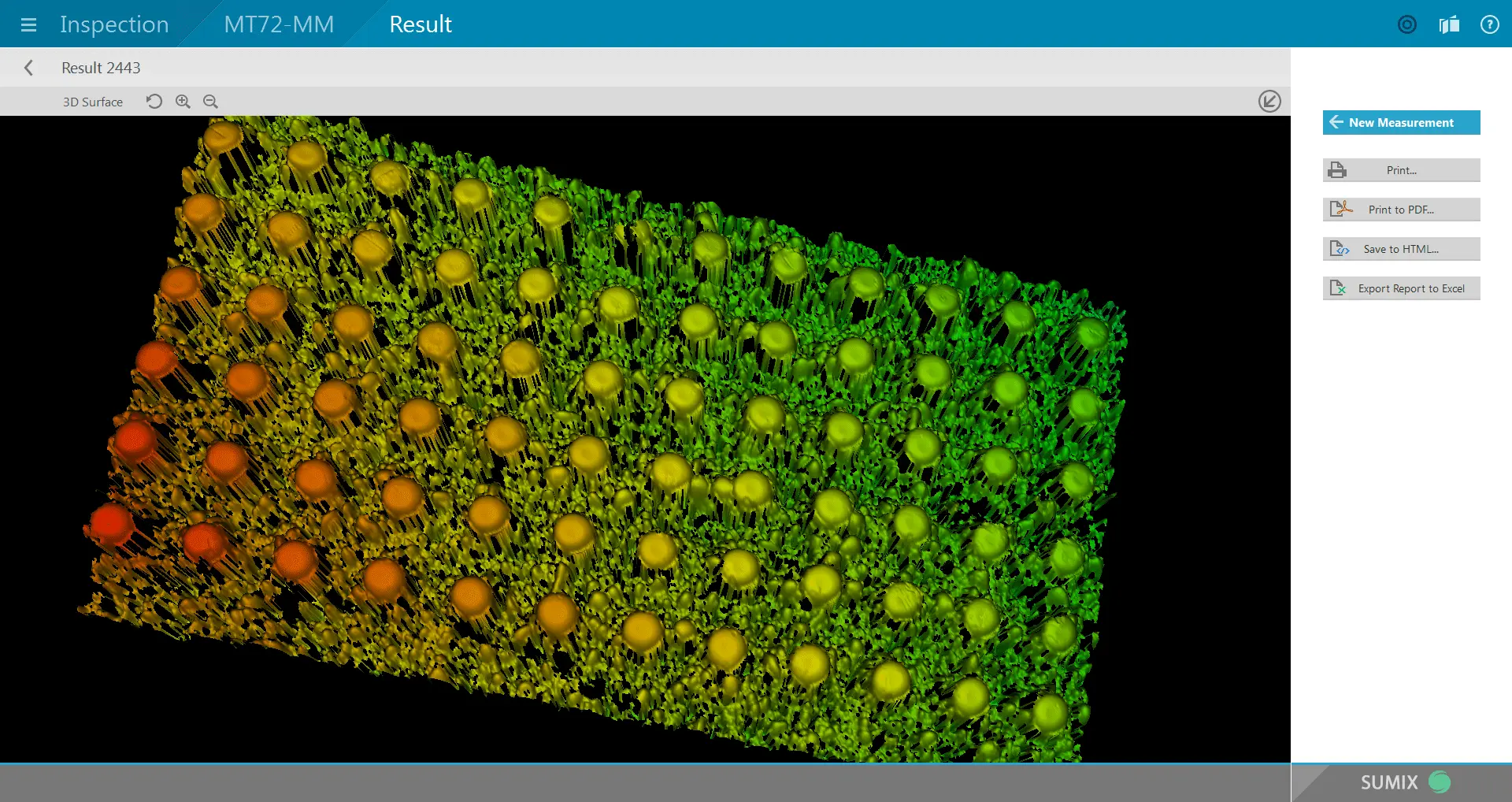

MT 24 connector: Surface 3D view.

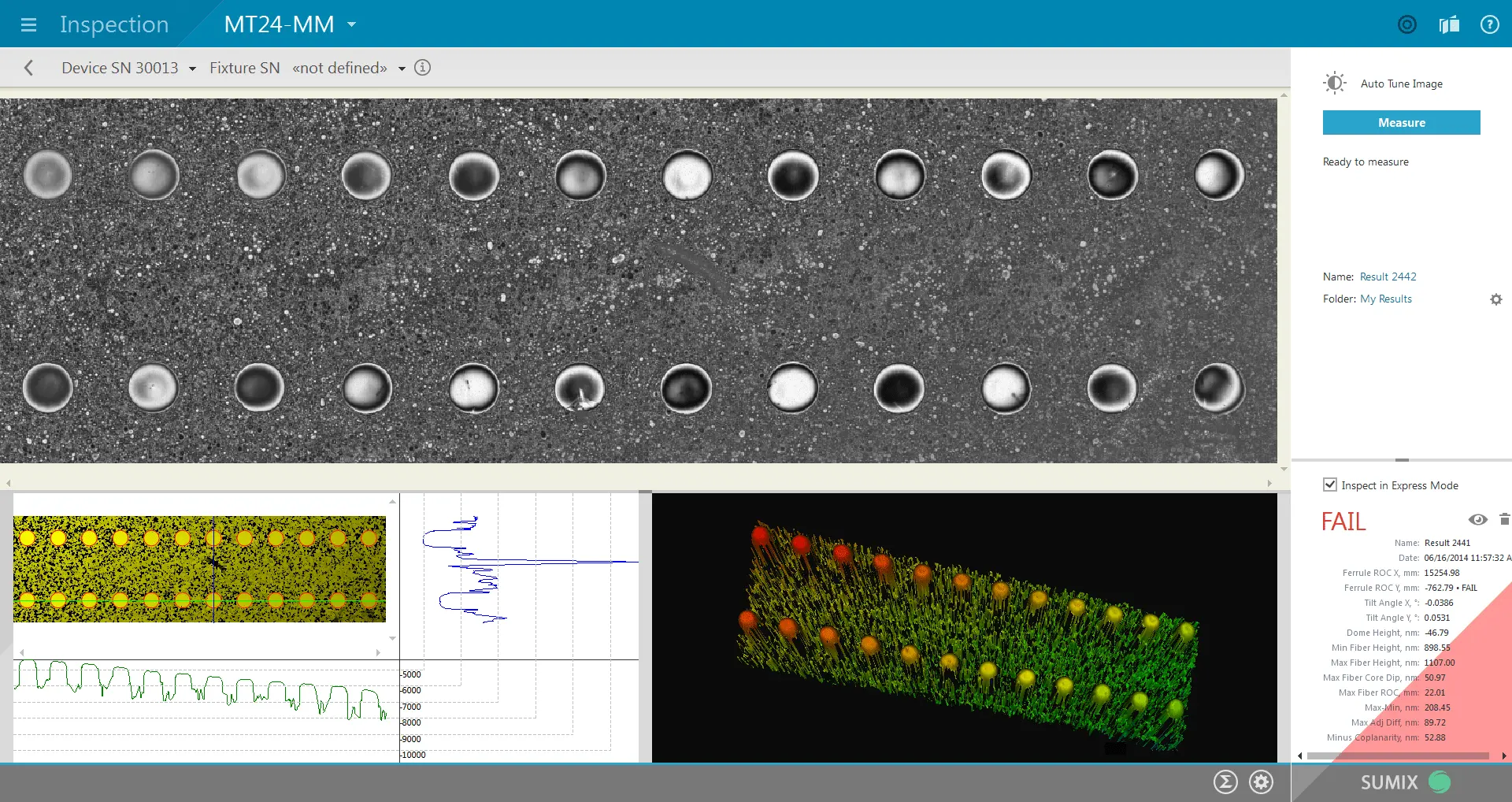

MT 24 connector: Measuring in Express mode.

MT 72 connector: Surface 3D view.

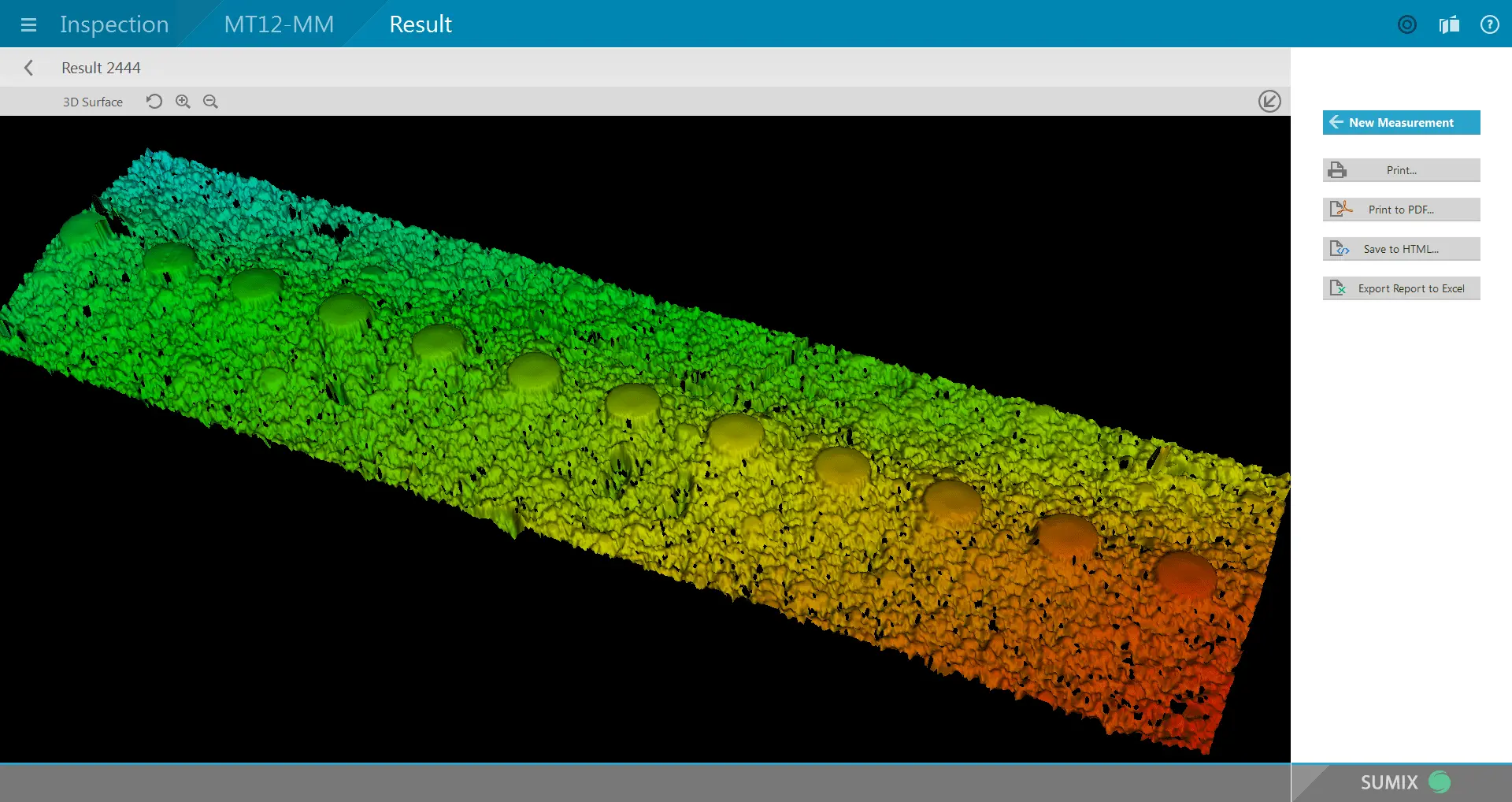

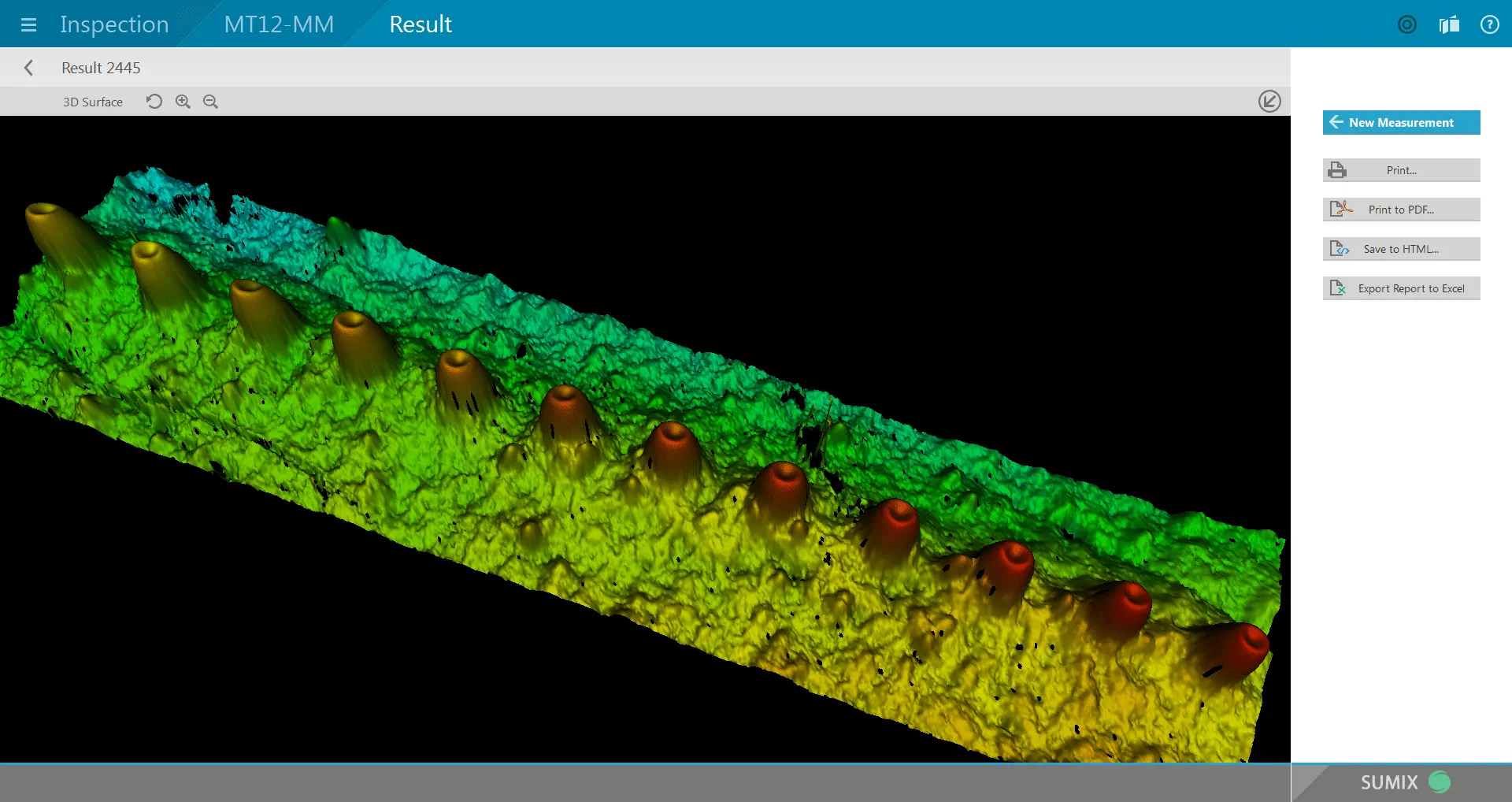

MT 12 connector: Surface 3D view.

MT 12 connector: Surface 3D view.

MT 12 connector: Measuring in Express mode with the summary statistics.

MTRJ Singlemode connector: Surface 3D view

E2000 is a trademark of Diamond SA.

MTP is a registered trademark of US Conec Ltd.

CS is a registered trademark of Senko Advanced Components Inc.